By Reginald Tucker

Large enough to maximize the production capabilities befitting a leader in the U.S. hardwood flooring arena, but nimble enough to make timely adjustments in manufacturing and sourcing to address shifting demand both domestically and abroad. That sums up AHF Products’ current approach to the market as it tweaks its production strategy amid evolving consumer tastes, tariffs on imports from China and challenges posed by the coronavirus pandemic.

Not too long after Brian Carson, president and CEO of AHF Products, took the helm at the company following its spin-off from Armstrong Flooring, the company went into rapid investment and expansion mode. One of the first moves AHF Products made was the 2019 acquisition of LM Flooring, a highly regarded hardwood flooring manufacturer based in Sihanoukville, Cambodia. The primary purpose was to expand its repertoire to include sliced- and sawn-face product offerings, which fall under LM Flooring’s specialties. But the move also resulted in additional benefits.

“We looked at the products we made here at AHF, and there were certain areas where we had gaps,” Carson told FCNews. “The growing sliced- and sawn-face engineered products was something that we really didn’t have the manufacturing capability to do; we were just another company sourcing the product.”

Not anymore.

With the pickup of LM Flooring, Carson noted, AHF Products in an instant added world-class manufacturing capability via two plants—one in Cambodia; the other in China—along with world-class styling, product knowledge and expertise. Since that time, the Shanghai plant has closed and its resources (including equipment and personnel) were allocated to the Cambodian facility. “Our goal was to vertically integrate into sawn and sliced faced, because that was an opportunity for us to create real value by manufacturing,” Carson explained. “We saw an opportunity to provide products that people really desire.”

Moreover, LM Flooring had a footprint in a place where AHF Products wanted to expand. Now, it appears, the fruits of its efforts are being realized. A year ago, the LM Flooring facility in China was bigger than the facility in Cambodia. But over the past 16 months, AHF Products has tripled the size of the Cambodian operation and exited China altogether. Today, the Sihanoukville facility produces about 30 million feet a year, up from roughly 8 million feet when it acquired the plant. That number is only expected to rise even higher in the near future.

“As we speak, we are installing new, state-of-the-art equipment in there,” Carson said. “We’ve also added two more buildings, and we bought the land next door. Plus, we’re in the process of adding 500 people as well as a dormitory for the employees. That facility is going to be a 50-million-foot plant as we move into next year.”

AHF Products said it expects the scale-up process to be smooth and seamless, thanks in large part to the experience of the people who will be running the plant. According to Carson, seven managers have relocated to Cambodia from Shanghai, and they will be joined by experts from AHF Products’ U.S.-based operations.

“When you acquire a company or put two companies together, you’re buying technology and you have the relationships as well,” Carson explained. “But the other thing you’re getting in the deal is management talent. We didn’t know how to make these products, and we didn’t know how to operate in this part of the world. It was very important to us that we were able to keep that and transfer that knowledge, a winning attitude and the styling capabilities and the process control from our Shanghai facility to our Cambodian facility.”

With respect to specific formats, the Cambodian facility is designed for maximum flexibility. According to Carson, it can produce formats ranging from 3-inch-wide planks up to 10- inch-wide boards x 4 feet long up to 8 feet long. “The plant comes with some phenomenal capabilities,” he said. “This includes four finishing lines, which gives us a tremendous amount of flexibility for visuals, textures, gloss levels and different colors.”

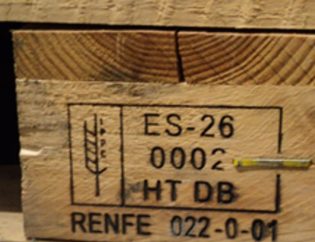

More importantly, the investments equate to a higher level of confidence for AHF Products’ customers. “Yes, we have wonderful brands and the styling is just fantastic coming out of the plants,” Carson stated. “But you also have the stability of duty-free, tariff-free products along with the confidence of compliance that we’re making the products the right way. That includes everything from the treatment of the wood to the conditions in the plant and the dormitory facilities. We bring all of that.”

Beyond the North American market, the Cambodian facility will service customers in Europe, Australia, Asia and New Zealand.

Stateside expansion

While AHF Products continues to strengthen its manufacturing footprint in Asia, the company is also shoring up its manufacturing operations in the U.S. in support of its growing stable of powerhouse brands. These initiatives range from adding shifts at its Somerset, Ky., facility, where the company produces engineered flooring, to fortifying production at its Beverly, W. Va., plant, which primarily manufactures solid hardwood products.

“Cambodia is obviously important, but it’s just one leg of a four-legged stool,” Carson stated. “We have new capabilities and additional capacity going into all of our solid and engineered plants in the U.S. We’re adding new equipment, new technology and staffing as we speak. We’re talking about more than 100 new jobs by the time we’re done.”

With the investments in the Somerset plant, for example, AHF Products will be able to manufacture the aforementioned sawn- and sliced-faced products currently produced in Asia. This will result in quicker lead times for those types of products. The company said it is also quietly working on an exciting new (patented) innovation that, according to Carson, will be a game-changer. “We’re not ready to provide more details about it now, but I promise it will knock your socks off,” he said. “It is going to breathe tremendous life into the wood category to the bene- fit of everybody.”

Vietnam Plywood

Vietnam Film Faced Plywood