We’re all familiar with plywood, but did you know there are different types of it? Plywood comes in grades and fits into 1 of multiple different categories, depending on its composition and how it was made. Marine-grade plywood, for instance, is the highest grade of plywood and differs from other types of plywood in many ways.

In case you weren’t aware of marine-grade plywood and what gives it its name, let’s go through a complete breakdown of everything you could hope to know about marine-grade plywood.

What is marine grade plywood?

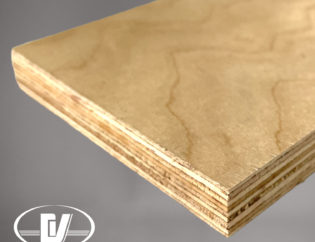

Marine grade plywood (also known as marine plywood), is a premium grade timber product designed specifically for water-related applications. It consists of multiple layers of wood veneers bonded with water-resistant, weather, and boil-proof (WBP) glue.

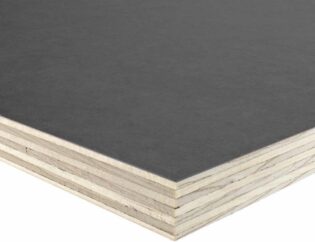

To make marine plywood, manufacturers typically usetimber sheets from tropical hardwood. They arrange 5 or more plies in a perpendicular manner. This allows the grains to be in an alternating manner from vertical to horizontal.The manufacturers then bond the plies under heat and pressure.

They also use waterproof adhesive to keep the sheets together. They wrap up production by applying a water-resistant finish to the plywood exterior.What sets marine plywood apart from other plywood is its lack of voids. It also doesn’t have any knots or air pockets. This, along with its use of waterproof glue, is the plywood’s defining feature.Most plywood products use fewer, thicker layers of lower-quality wood. However, marine grade plywood uses more, thinner layers of high-quality wood.

When exposed to water or high humidity, marine plywood exhibits excellent resistance to rotting, shrinking, and warping. This enhanced water resistance is achieved through the construction process. While regular plywood is typically made using three glued-together plies of wood, marine grade plywood can be constructed using as many as five or more layers, bonded with waterproof adhesive. This construction method ensures optimal strength and durability, even in marine environments.

Is marine plywood waterproof?

It is made from durable face and core veneers, with minimal defects, ensuring prolonged performance in wet conditions. Its structure allows for long-term use in environments exposed to moisture. However, it is crucial to note that marine plywood is not entirely waterproof and can still be affected by prolonged exposure to water or high humidity levels. Also, this can vary according to the grades of Marine plywood.

When used outdoors, we recommend that all edges and the back face are fully sealed with an appropriate gap-filling sealant. Manufactured with fully waterproof WBP Melamine top glue (tested for immersion and boiling water), marine plywood can be used in waterborne applications on walls, tiled floors, and for cladding and decking.

The key difference between marine plywood and regular plywood lies in their composition and the number of layers used in construction. As implied by its name, marine plywood finds its primary use in marine endeavors like constructing boats, yachts, and similar waterborne projects. Its resilience against moisture and robust strength render it a perfect option for water-exposed structures such as docks, piers, and outdoor furnishings situated in coastal regions.

When should you use marine grade plywood?

As mentioned before, marine plywood uses an impeccably durable and versatile sheet material, especially when using it in water applications. Beside these benefits, marine plywood price is not higher than that of regular plywood but you should make the right choice on your investments. So when should you consider marine plywood? We recommend you some of the prime projects:

1. Boat building

Regardless of the size of the boat, you are building; marine plywood sheets are the best materials to use. The material is durable, easy to work with, and will protect your boat in case of a leak

2. Docks

Marine plywood is an excellent option for docks. While other wood types need sanding and annual treatment, the case is different for marine plywood. It withstands harsh environments with little maintenance every year. As such, it doesn’t warp or rot due to water conduct.

3. Flooring

Marine plywood is also an excellent option for making cabinets and flooring, depending on the amount of water these places come in contact with.

4. Kitchen cabinets and kitchen furniture

Because it does not retain water, marine plywood is an excellent choice for kitchen cabinets and kitchen furniture. It are exposed to high levels of moisture, steam, and water from overflowing sinks, pressure cookers, kitchen appliances, leaky faucets, and so on.

5. manufacture outdoor furniture

It is at risk of exposure to rain, such as garden benches, tables, swings, and lounge chairs.

Exploring the unique features of marine hardwood plywood

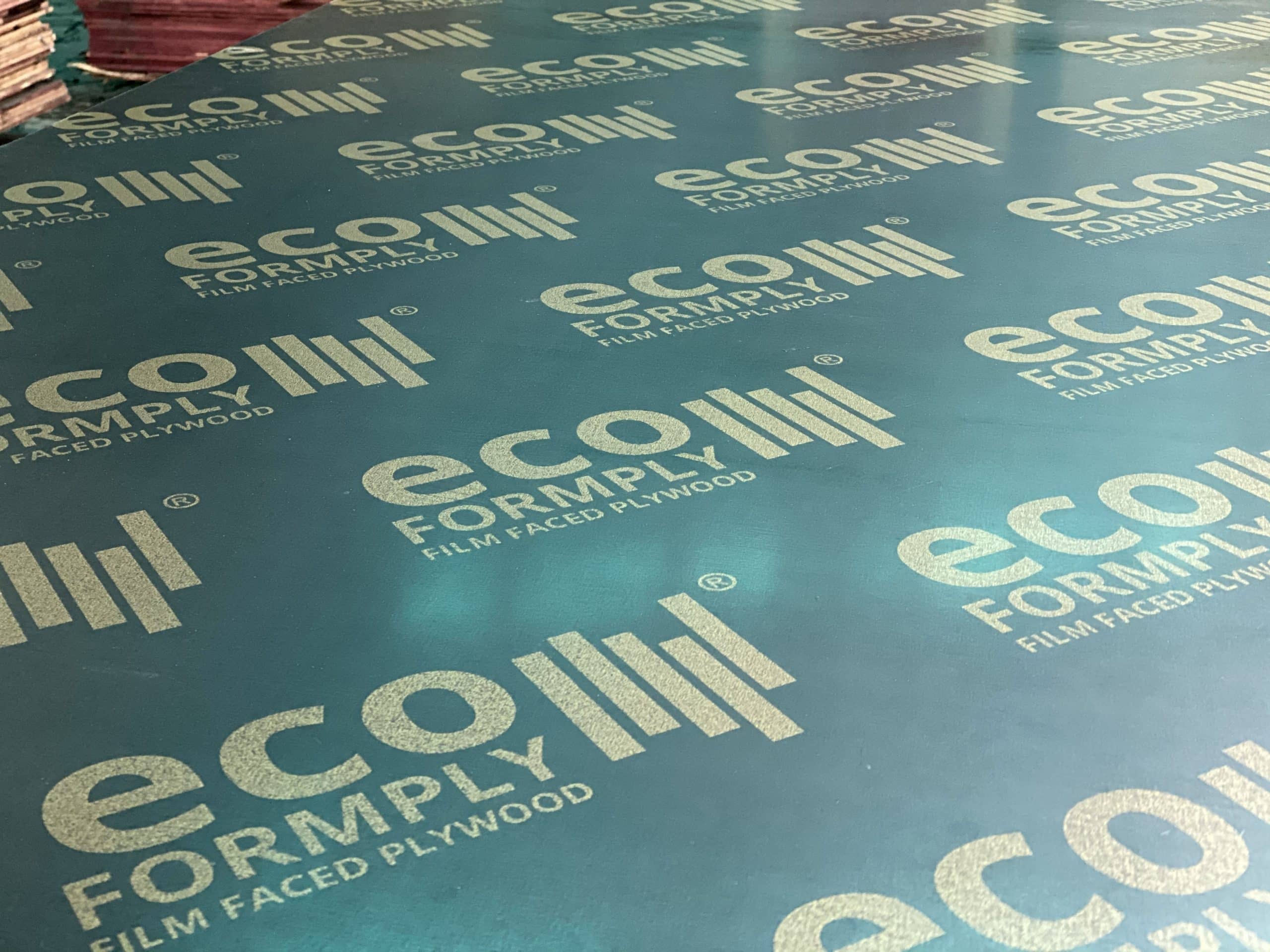

Vinawood Marine Plywood is the go-to option for lasting water-resistant solutions. Let’s explore some outstanding features of marine plywood.

1. Marine plywood uses high quality modified resin

The adhesives used in making marine plywood are synthetic plastic resin, basically, a Phenol Formaldehyde resin that is known to have great adhesive quality. Use of good quality resins helps block all the moisture and water. Good brands use undiluted resin so that the quality of the plywood is not compromised with.

2. They are used for exterior and high water-exposure applications

Mentioned earlier, these plywood have a great threshold for water exposure. Hence, marine-grade is used outdoors as garden furniture or staircases. Going by the name, they are used in the boat-making industry where exposure to water is high. They are preferred for bathroom and kitchen applications for the same reason.

3. Marine-grade plywood has unmatchable strength

Use of good quality resins and timber, make marine plywood the strongest in the plywood industry. They are known for their strength and durability. The waterproof aspect of these ply retains the integrity of your furniture.

4. They are heavy on the wallet

As compared to the moisture-resistant variant, commercial plywood, marine-grade plywood are generally twice as expensive. Marine plywood price differs from brand to brand, however, the plywood sheet price differs more because of the quality of resin and timber used to manufacture them. The utility of marine plywood is vast which could affect the marine plywood price in the plywood industry. They have an extraordinary surface finish for both residential and commercial purposes.

5. Versatility of Marine plywood

Another advantage of marine plywood is its versatility in terms of surface finishes. It provides an extraordinary surface finish, making it an ideal choice for both residential and commercial purposes. Whether you prefer a smooth and polished appearance or a textured and rustic look, marine plywood can be easily customized to suit your aesthetic preferences. This versatility allows for endless design possibilities and creative expressions.

6. Excellent Stability of Marine plywood

Furthermore, marine plywood is designed to withstand various weather conditions and extreme temperatures. It has excellent dimensional stability, meaning it maintains its shape and size even when exposed to moisture, heat, or cold. This feature is crucial, especially in applications where the plywood may be subjected to significant temperature fluctuations or high humidity levels.

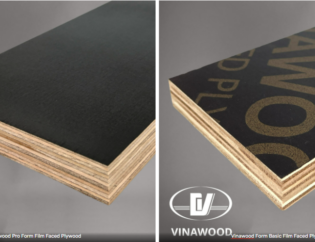

Marine plywood offered by Vinawood is impact-resistant and the hard exterior makes it scratch-proof. These features contribute to their popularity for commercial and residential constructions.

Vinawood offers a wide range of premium, boiling water-proof marine grade plywood. They are completely waterproof in nature, made with pre-pressing which gives them enhanced durability and longer life. It has more plies for added strength. It is borer and termite proof, protecting your interiors from untimely decay.

Pros and cons of using marine grade plywood

Applying marine plywood has both advantages and disadvantages. Here are some of the most typical pros and cons:

Pros

Durable — Marine plywood inherits its parent wood’s natural durability. The plies’ unique arrangement and bonding also add to the plywood’s toughness.

Pliable — This plywood has excellent pliability compared to other structural plywood. You can bend or shape it any way you like without breaking easily.

Impact-resistant — The plywood’s hard exterior makes it resistant against impact damage. It doesn’t easily sustain any dents even when dropped accidentally.

Water-resistant — The weather and boil proof glue used to make the plywood helps give its water resistance. Manufacturers also typically apply a water-resistant finish to protect it from moisture and humidity.

Readily available — Marine grade plywood is easily available on the wood market. You can also buy it in different lengths and thicknesses. Unlike solid wood products, this plywood is available in large sizes.

Cons

Chemicals — Just like other plywood products, marine plywood can also contain chemicals. These are used to help protect its wood veneer from ants and termites. However, these same chemicals can also be harmful to people’s health, especially their lungs.

We recommend buying plywood only from suppliers who sell volatile organic compound (VOC)-free timber products.

Expensive — Marine plywood is not as affordable as other engineered wood like Medium Density Fiberboard (MDF). The higher the plywood grade, the more expensive it gets.

Where to buy plywood?

When looking to buy plywood, it’s essential to find a reputable supplier that offers high-quality products to ensure the success of your project.

Online retailers provide a convenient option for purchasing plywood, offering a wide selection of types, grades, and sizes to suit various needs.Vinawood is confident to become your long-term partner with high-quality products and reasonable prices. Whether you’re a DIY enthusiast or a professional contractor, choosing the right supplier ensures you get durable and reliable plywood for your construction, woodworking, or home improvement projects.

As a leading plywood supplier in Vietnam, Vinawood committed to providing our customers with a wide range of high-quality products to meet their specific needs. Two popular products of plywood that our company prouds of are Marine Extra Plywood and Marine Standard Plywood.

Our plywood is manufactured using premium materials and advanced techniques, ensuring superior strength, durability, and dimensional stability. Whether you need plywood for construction, furniture, formwork, or any other application, we have the right solutions to meet your requirements.

Our dedicated team consists of highly skilled professionals with extensive industry experience. From production to quality control and customer support, our experts work diligently to ensure the highest standards are met at every stage. We continuously invest in our team’s training and development to stay updated with the latest industry trends and techniques, enabling us to deliver innovative solutions tailored to your specific needs.

Conclusion

With the name ‘Marine’, it’s easy to imagine this type of plywood being associated with docks and boats moored nearby. And indeed, it can be. However, coastal or waterfront projects aren’t the only perfect fit for marine plywood. Indeed, one should not pigeonhole marine plywood based solely on its name and limit its use to waterfront settings.

This type of plywood has vast utility and applications, especially in high-moisture environments. Just take a good look around from where you’re sitting, whether it’s your office space or your modern home. From office floors to family kitchen cabinets, this plywood can work wonders for all sorts of projects and thus dominates the world of furniture dominated by this marvelous material.

In summary, marine plywood is nothing but a more water-resistant version of waterproof plywood. For the features, characteristics, and uses mentioned above, it has long been and continues to be considered the best type of plywood for high-moisture areas.

You can find Marine plywood in two standards: extra and standard, each varying in quality, thickness, and cost (extra being the highest quality and standard relatively lowest). So if you’re considering starting a project that requires the use of marine plywood, understand which type of plywood will work best for your project.

At Vinawood, we take immense pride in being a renowned Plywood factory, manufacturer, and supplier based in Vietnam. With our unwavering commitment to excellence, we have garnered a reputation as a trusted provider of high-quality plywood products worldwide.

With a focus on customer satisfaction, we offer a wide range of customizable solutions to meet the specific requirements of our esteemed clients. Moreover, our products are compliant with industry standards, and we can provide you with a certificate of authenticity for added assurance.