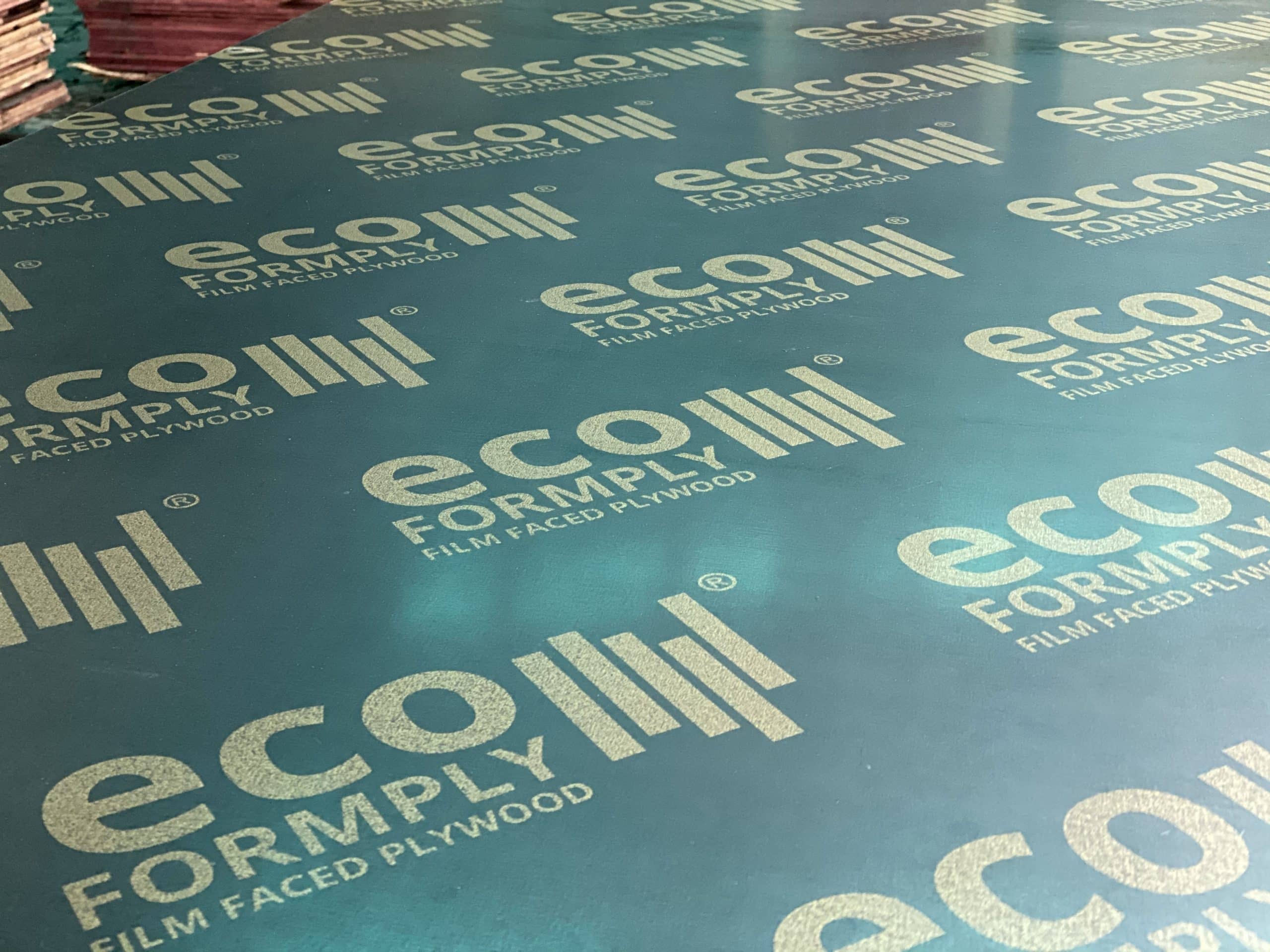

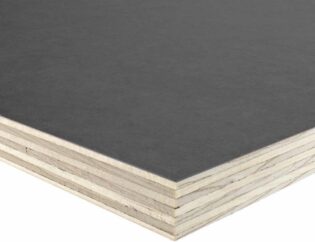

Vietnam, known for its high-quality wood products, is home to one of the leading plywood suppliers globally – Vinawood. Among its top-quality offerings is Medium Density Overlay (MDO) plywood. MDO, a top choice for construction, signage, and marine applications, is preferred for its durability, surface quality, and versatility.

MDO is made from strong, dense hardwoods, covered with a medium-density overlay. This overlay provides a smooth and paintable surface that’s weather and wear-resistant. Vinawood’s MDO is supplied in a standard size of 3/4-in x 4-ft x 8-ft, which is ideal for diverse applications.

Proper care and handling are essential for MDO plywood, as with any wood product, to maintain its quality and prolong its lifespan. Here are some tips for storing, handling, and using MDO plywood from Vietnam:

Storing MDO Plywood

- Indoor Storage: Despite MDO’s weather-resistant overlay, it is best stored indoors to protect it from excessive moisture and ensure longevity.

- Flat Surfaces: Always place MDO plywood on flat pallets that provide ample support to the entire surface, preventing sagging and maintaining the flatness of the sheets.

- Level Surfaces: Make sure to store the pallets on a level surface to avoid any unnecessary pressure points on the plywood.

- Edge Protection: The edges of plywood are susceptible to damage. Consider using protective materials such as foam or rubber to safeguard them.

Handling MDO Plywood

- Lifting over Dragging: Always lift sheets instead of dragging them to prevent scratches and surface damage.

- Two-Person Job: Due to the size and weight of the plywood sheets, it’s recommended that two people handle them to avoid accidental drops or damage.

Using MDO Plywood for Concrete

- Apply a Release Agent: Before pouring concrete, apply a release agent to the MDO plywood form to prevent concrete from sticking to it, ensuring a smooth removal after the concrete has cured.

- Secure the Forms: Ensure the MDO plywood forms are secure before pouring concrete. Any loose fasteners or braces could lead to form failure.

- Proper Pouring: Avoid dropping concrete from a height as it can exert pressure and potentially damage the form. Instead, place the concrete and allow it to flow within the form.

- Time the Removal: Allow adequate curing time before removing the forms. Early stripping can damage the concrete surface.

- Clean the Forms: After stripping, clean the forms thoroughly to remove any concrete residue. The cleaner the forms, the longer they will last.

Remember, as a trustworthy plywood manufacturer and plywood supplier, Vinawood is committed to providing top-quality MDO and film faced plywood products. With Vinawood, you are ensured of the highest standards of plywood that make your construction projects stand out.