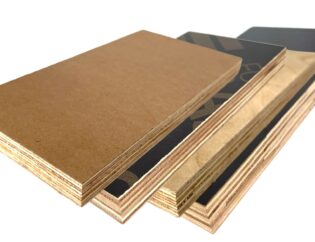

SF Gate– Plywood is a versatile wood product with applications ranging from woodworking to home building. Manufacturers shave thin wood layers, called veneers, from logs. They flatten and grade the veneers, then glue them together in a process that uses heat and pressure. Different types of plywood have different grades and specifications that indicate their allowable use, appearance and strength.

Veneer Grades

The veneer layers receive a grade letter from A to D, or N. Grades A and N have the best appearance with no visible repairs and no knots. Grade-N veneers are intended for a natural finish and grade-A veneers for a painted finish. Grade-B veneer may have a few small knots and a few patches. Sheets of veneer with small, open knotholes and larger, patched holes are graded C. If all the knotholes are patched, the veneer receives a grade of C-plugged. On grade-D veneer, knotholes are not patched at all.

Plywood Letter Grades

Each face of a sheet of plywood receives a letter grade according to the veneer grade assigned to it. For example, BC plywood has one B-grade face and one C-grade face. Manufacturers usually sand grades N, A and B to a fine finish. Faces with grade-C or grade-D veneers may receive a light sanding to remove imperfections, depending on the application. The grades of the interior veneer layers affect strength, exposure rating and application.

Exposure Specifications

The exposure specification indicates the allowed exposure to moisture for the plywood. Interior plywood, suitable only for protected, interior use, receives an exposure grade of INT. Exposure 1, or EXP 1, allows exterior exposure to the elements for a limited period of time during construction. Exposure 2, or EXP 2, also called IMG, allows less exposure to moisture or humidity. EXT is for exterior applications that include permanent exposure to the weather.

Plywood Strength

Plywood span ratings indicate the distance between framing members for roofing and flooring. The span rating looks similar to a fraction and gives the roof span first and the floor span second. For example, 24/16 indicates that the distance between two framing members must not exceed 24 inches on a roof, and 16 inches on a floor. Other strength factors are specified in tables provided by the Engineered Wood Association.

Grading Stamps

The Engineered Wood Association governs plywood grading and allows the use of a stamp with the logo APA in the top section to identify the type and grade of plywood. The first line in the middle section of the stamp indicates the intended use of the product. The next line lists the span rating, followed by the plywood thickness. The bottom line of the middle section gives the allowed exposure. The middle of the line in the bottom section displays the two face grades of the sheet.