Plywood Overview & Applications

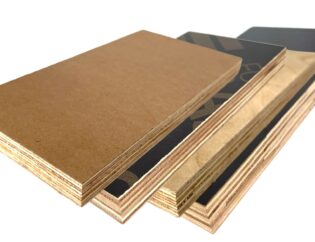

Wood Solutions– Plywood is wood veneers bonded together to produce a flat sheet. An extremely versatile product, plywood is used for a wide range of structural, interior and exterior applications – from formwork through to internal paneling.

Plywood is an assemblage of wood veneers bonded together to produce a flat sheet. While it can be tailored to suit an extensive range of applications, the normal product consists of at least 3 plies, with the grain in the alternate plies running at right angles.

There are four groupings of plywood products, with each group designed for specific applications:

Structural

Exterior

Interior

Marine.

Plywood offers the following benefits:

Increased stability

Plywood offers all the inherent advantages of the parent wood plus enhanced properties in its laminated structure.

High impact resistance

Being a wood based material, plywood has the ability to accommodate the occasional short-term overload; up to twice the design load. This is useful where seismic activity or cyclonic winds can occur. This property is also effective when used as construction flooring or as concrete formwork. Plywood’s laminated structure distributes loads from impact over a larger area on the opposite face, which effectively reduces the tensile stress.

Surface dimensional stability

The cross laminated construction of plywood ensures that plywood sheets remain relatively stable under changes of temperature and moisture. This is especially important in flooring and formwork construction where moisture exposure is very likely.

High strength to weight ratio

With high strength and stiffness to weight ratios, plywood is very cost effective to use in structural applications such as flooring, shearwalls, formwork and webbed beams.

Panel shear

The panel shear of plywood is nearly double that of solid timber due its cross laminated structure. This makes plywood a highly effective material to use in gussets for portal frames, webs of fabricated beams and as bracing panels.

Chemical resistance

Plywood does not corrode and can be used in chemical works and cooling towers as a cost-effective, durable material when preservative treated.

Applications

Cladding, External

No other cladding material can offer the design freedom, ease of handling, range and natural beauty of timber. Timber cladding can create a building to suit almost any environment, taste or style.

Timber cladding has an inbuilt flexibility that provides natural advantages on sites subject to high winds, extreme climate, highly reactive soils, subsidence or earth tremors. And unlike masonry and other rigid materials, the natural resilience and high strength to weight ratio of timber enables it to withstand far greater stresses and movement.

Modern finishes give a long lasting and attractive appearance to timber cladding and can be used to change the colour and style of the building, making it a versatile material that will keep pace with changing tastes and fashions.

Doors

Whether manufactured from solid or engineered timber, there are many stylish and practical options that won’t compromise on strength and structural performance. A distinctive timber door can also create visual impact, adding value to any commercial or domestic building.

Timber makes an attractive choice for door design and construction, offering a strength, flexibility and versatility that other materials find hard to match.

Protected from moisture, a timber door will perform satisfactorily for the life of any building. With regular maintenance, carefully designed and finished timber doors can perform in the toughest external environment and if required, can be refurbished or updated easily and effectively.

This application guide outlines the common elements involved in specifying and finishing timber internal and external doors.

Flooring

Whether for structural or finished flooring applications, timber offers durability, versatility and adaptability. The warmth, strength and natural beauty of timber flooring has proved enduringly popular in a wide variety of interior settings.

Timber flooring is a timeless product, offering a warmth and natural beauty largely unmatched by other flooring options. This article provides an overview of the installation of solid timber strip flooring over bearers and joists, timber based sheet flooring products and concrete slabs. Timber flooring is typically supplied as either solid timber or laminated wood products, made from layers of bonded timber. It fits together with a tongue and groove joint and once in place, is sanded and finished. There is a wide variety of species to select flooring from and the right species for a given application will be dependent on numerous factors. Information relating to species selection, environmental assessment, finish selection and recommended maintenance routines are all provided in this section.

Framing

Lightweight timber construction typically comprises framed and braced structures to which one or more types of cladding are applied. Framing configurations can range from the closely spaced light timbers commonly seen in stud frame construction to large, more widely spaced timbers. A timber framed building can be placed on a concrete slab or on posts/poles or bearers resting on piers/stumps supported on pad footings.

Used in houses or multi-residential dwellings, lightweight timber construction offers the flexibility of a wide range of cost effective design options.

When the timber comes from sustainable sources, this construction method can be environmentally advantageous as it combines timber’s low embodied energy with its capacity to store carbon.

Joinery

Timber joinery products offer a classic, unique and stylish touch to any interior or exterior design. The products are produced for a variety of internal applications including door and window frames, cabinetry, skirtings, mouldings and architraves. When looking to the outdoors, joinery products range from decorative eaves and posts to eye-catching railings.

Many timber species are suitable for joinery products and care should be taken in selecting the perfect timber for the particular product and its intended finish. Rare and exotic species such as Teak and Rosewood can generate pieces of outstanding beauty but material cost and availability are also important considerations.

Commercially available species like Tasmanian oak, Australian cypress, spotted gum and the like, often make the more practical choice, with the added benefit that they can be easily matched with other timber products within the building, like flooring.

Solid timber for joinery products is generally supplied as ‘clear finish grade’ but ‘paint grade’ options are available and these are usually comprised of a composite material like MDF or glulam.

A large number of specialist suppliers and producers offer the consumer extensive choice of profiles for all of the most common and popular joinery products. Choice is in many cases, limited only by imagination.

Cabinetry is often associated with joinery and most typically includes, cupboards, benches and other similar ‘built in’ furniture. Like joinery, cabinetry is generally specified as either paint or clear finish grade and naturally for clear finish grade timbers, appearance and surface finish are critical in achieving a successful application.

Panelling, Interior

Internal panelling, also known as appearance boards and linings, is not just a practical means of covering one or more walls and ceilings in a building, its inclusion in a room’s interior design can generate looks that are both dramatic and stylish. Internal paneling comes as either solid natural timber paneling or as sheets of engineered wood products that provide a durable and hardwearing surface for areas subject to high impact. As they typically function as appearance products they generally have no structural requirements. This guide describes the variety of panelling products available and outlines the straightforward process of installing them.

Portal Frames

Timber portal frames are one of the most favored structural applications for commercial and industrial buildings whose functions necessitate long spans and open interiors. As a material choice, timber offers designers simplicity, speed and economy in fabrication and erection.

Timber portal frames offer a strong, sound and superior structure. Structural action is achieved through rigid connections between column and rafter at the knees, and between the individual rafter members at the ridge. These rigid joints are generally constructed using nailed plywood gussets and on occasion, with steel gussets.

From material selection to finishing, this application guide provides a comprehensive overview of the process of using timber in the specification, fabrication and erection of portal frame structures.

Rails and Balustrades, Interior

The versatility, beauty and strength of timber makes it the ideal material choice for interior handrails and balustrades. Treated softwood and durable hardwoods are the most popular timber choices and these can be turned to create a range of unique styles and designs to suit a variety of tastes and decors.

When used internally balustrades and handrails are typically finished with a clear lacquer to showcase the natural beauty of the timber and with appropriate care and attention will last a lifetime. Find here general information on member sizes, connections and suitable materials, as well as important considerations, for the specification and construction of interior handrails and balustrades.

Shear walls

Framed timber buildings, of post and beam or stud and joist construction, resist lateral loads (wind, earthquake or impact) by using rigid frames (portals), braced frames (trusses and cross-bracing) or structural sheathing elements (diaphragms).

Diaphragms are an efficient structural solution to resist lateral forces. The sheeting materials that are generally used as lining or cladding can usually be upgraded to resist shear loads, easily and economically. The framing then performs dual functions, resisting both horizontal and vertical loads.

In cases where diaphragms comprise structural sheathing, additional design efficiencies can be incorporated to resist loads normal to walls, floor and roofs using the composite stressed skin action developed between the sheathing and the timber frame.

The advantages of timber shear walls and diaphragms include:

architectural design freedom (curves, cantilevers, clear spans)

lightweight construction

high impact load resistance

resilience (no brittle cracks)

fast conventional construction

In this section you’ll find information about the design and construction details of timber framed diaphragms (both horizontal and vertical) used in domestic, low rise commercial and industrial buildings.

Framing design for dead loads, or dead and live loads acting normal to the framing are covered in AS 1720.1 Timber Structures and AS 1684 Residential timber-framed construction. To develop efficient diaphragm action, some adjustments, particularly connection details, are usually required.

Information about diaphragm materials and systems is included, however the majority of the design and construction details provided herein are for structural plywood diaphragms for which documented design information is available.

Stairs, Exterior

All exterior stairs serve a functional purpose, but the choice of timber in the application will turn a functional building element into an aesthetically pleasing feature. And while the construction of stairs is demanding, the investment of time will be returned, with a well constructed timber staircase typically lasting decades.

Exterior stairs are usually built from treated softwood and durable hardwoods and typically finished with paint. The construction procedure described here applies to most general type stairs of either conventional or contemporary construction.

When it comes to stairs there is a multitude of variations available for application depending on the structural requirements of the building. This guide discusses the most commonly specified stair types.

Stairs, Interior

Interior staircase work is considered a specialised area of carpentry and joinery as its construction requires high levels of workmanship, detail and accuracy. Many interior stairs are built from quality joinery timber, cut and seasoned especially for staircases. Interior stairs differ considerably in design, from simple straight flights, commonly used in domestic work, to more elaborate stairs, constructed purposely as stand out features in public and commercial buildings.

The construction procedure described here applies to most general type stairs of either conventional or contemporary construction.