By Steven Baczek – Double-stud walls and trusses create the ideal shell for an economical and efficient building.

In this article, part 4 of the Passive House Build series, architect Steve Baczek explains how he designed the framing for a house that needed to meet the Passive House minimum for airtightness: 177 cfm50. He describes four elements of the framing: raised-heel roof trusses, which provided a quick way to hang and finish the ceiling air barrier before partition walls were built; the floor trusses, which allowed for easy running of mechanicals between the first and second floors; and the interior and exterior frames, which comprise the R-52 double-stud wall system. Air-sealing and insulating this house occurred in four phases, each of which included a blower-door test. Phase 1 was the construction of the primary air barrier, which was formed by the slab, the exterior sheathing, and the plastered ceilings below each roofline. Phase 2 was the application of a 4-in.-thick coat of closed-cell spray foam on the inner face of the wall sheathing. Phase 3 was the installation of the windows and doors, which resulted in higher blower-door numbers because of their inherent leakiness. Phase 4 was the installation of dense-pack cellulose in the walls, loose-fill cellulose in the attic, and mechanical systems. The result of this design and its careful execution was a final blower-door test of 110 cfm50, well below the Passive House minimum.

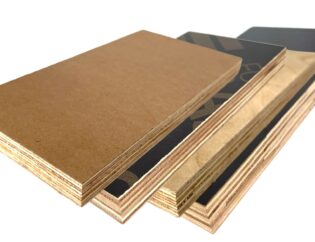

Vietnam Plywood

Vietnam Film Faced Plywood