In the world of construction, selecting the right materials can have a massive impact on the quality, longevity, and overall success of any project. This is particularly true when it comes to Medium Density Overlay (MDO) plywood, a material that is becoming increasingly crucial for formwork concrete applications. In this realm, Vinawood has carved out a niche as a premier manufacturer and supplier, offering products like the MDO 1S and MDO 1SF that elevate the MDO plywood standard.

The MDO Plywood Landscape

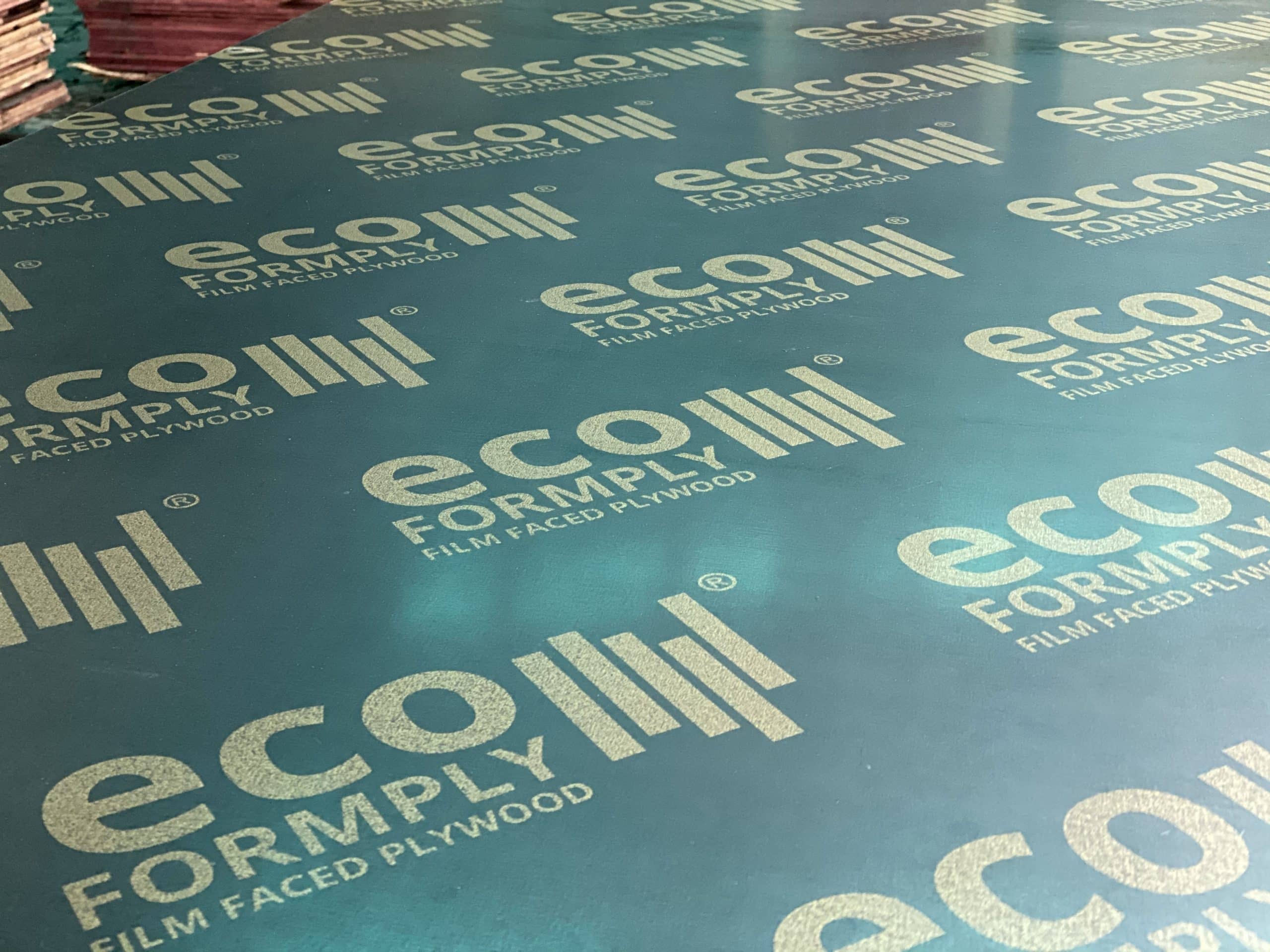

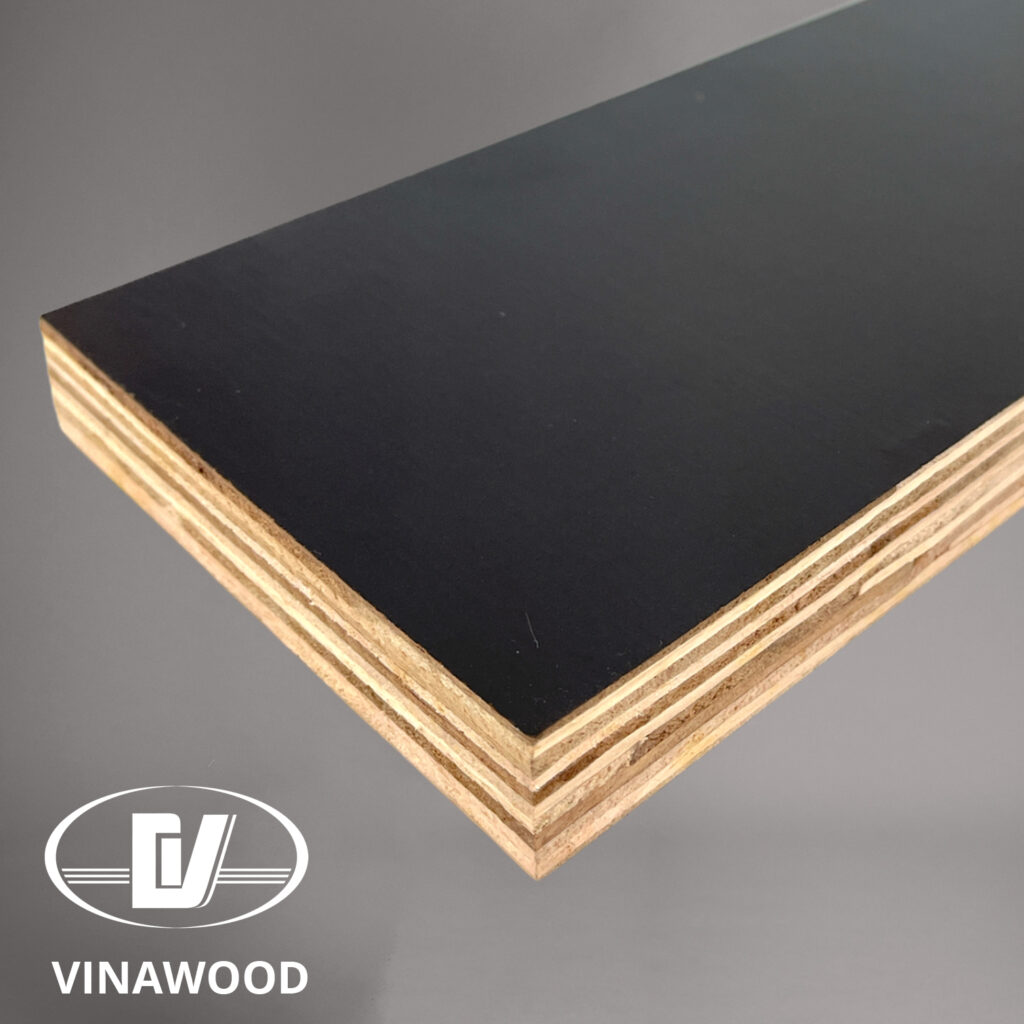

Crafted by combining a weather-resistant resin overlay with a wood surface under intense heat and pressure, MDO plywood provides a sturdy and smooth finish ideal for a range of construction applications, especially in concrete formwork.

The Vinawood Advantage

As a leading Vietnam plywood supplier and a renowned name in global markets, Vinawood has become synonymous with quality. Its MDO offerings, including the MDO 1S, not only challenge competitors but redefine the industry standards.

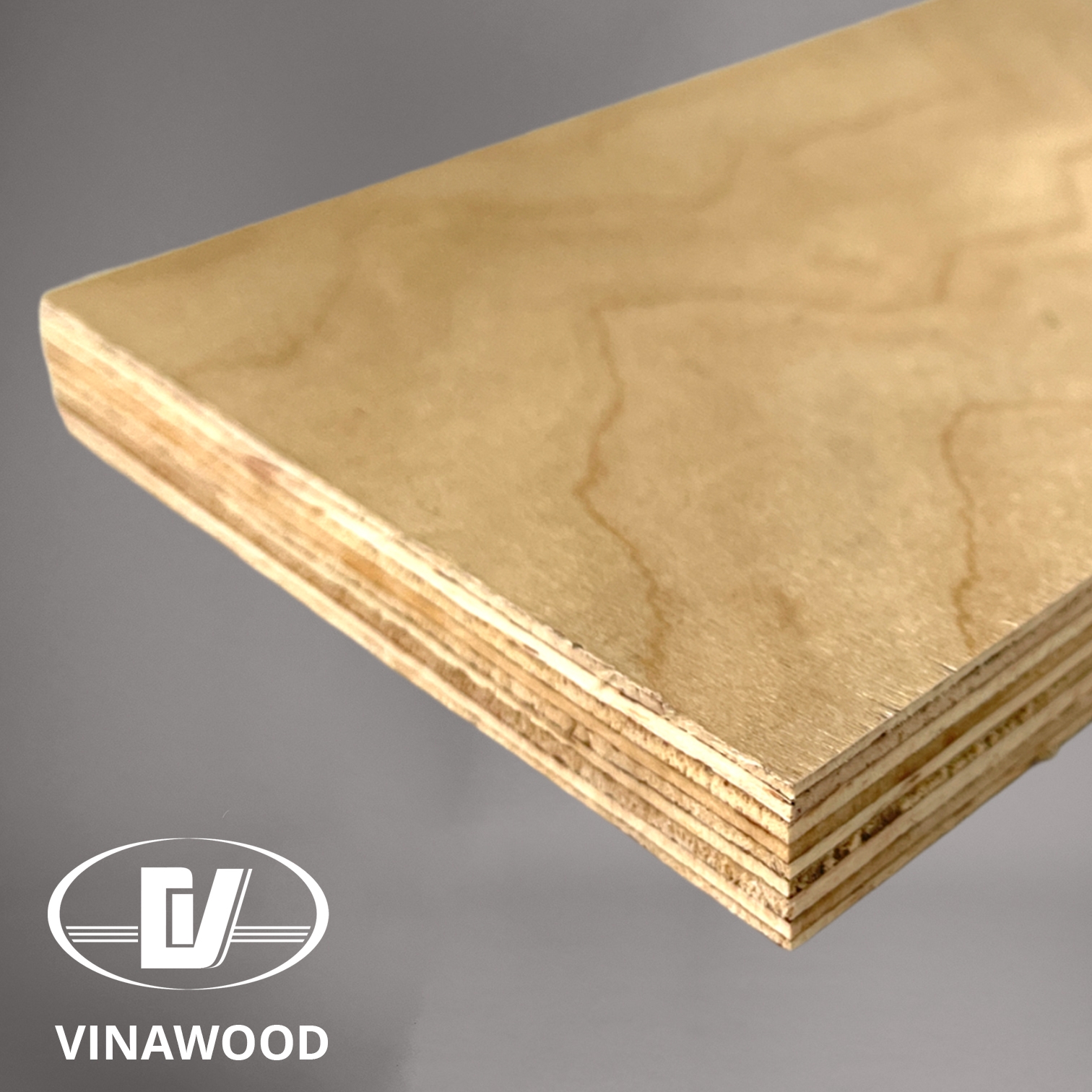

Vinawood’s MDO 1S: Raising the Bar for Durability

When compared to local MDO plywood in the USA and Latin America, Vinawood’s MDO 1S represents a significant step up in terms of durability and strength. However, like other MDO plywood lacking a protective film backer, MDO 1S can be susceptible to warping, twisting, and panel swelling.

Delving into the MDO 1S Technical Specifications

The MDO 1S comes in standard 4×8 sheets and offers a thickness of 3/4 inch. This MDO plywood variant boasts a sturdy surface, thanks to its medium-density overlay, designed to withstand the rigors of construction projects. Nonetheless, the lack of a protective film backer could leave the MDO 1S vulnerable to dimensional instability when exposed to harsh environmental conditions.

For density, MDO 1S typically falls in the range of 500-650 kg/m3, making it suitably dense for most applications. The absence of a backer does reduce some of its weather resistance, as its exposed back can absorb moisture more readily. However, its lower cost makes it a reasonable choice for applications where budget considerations may be paramount.

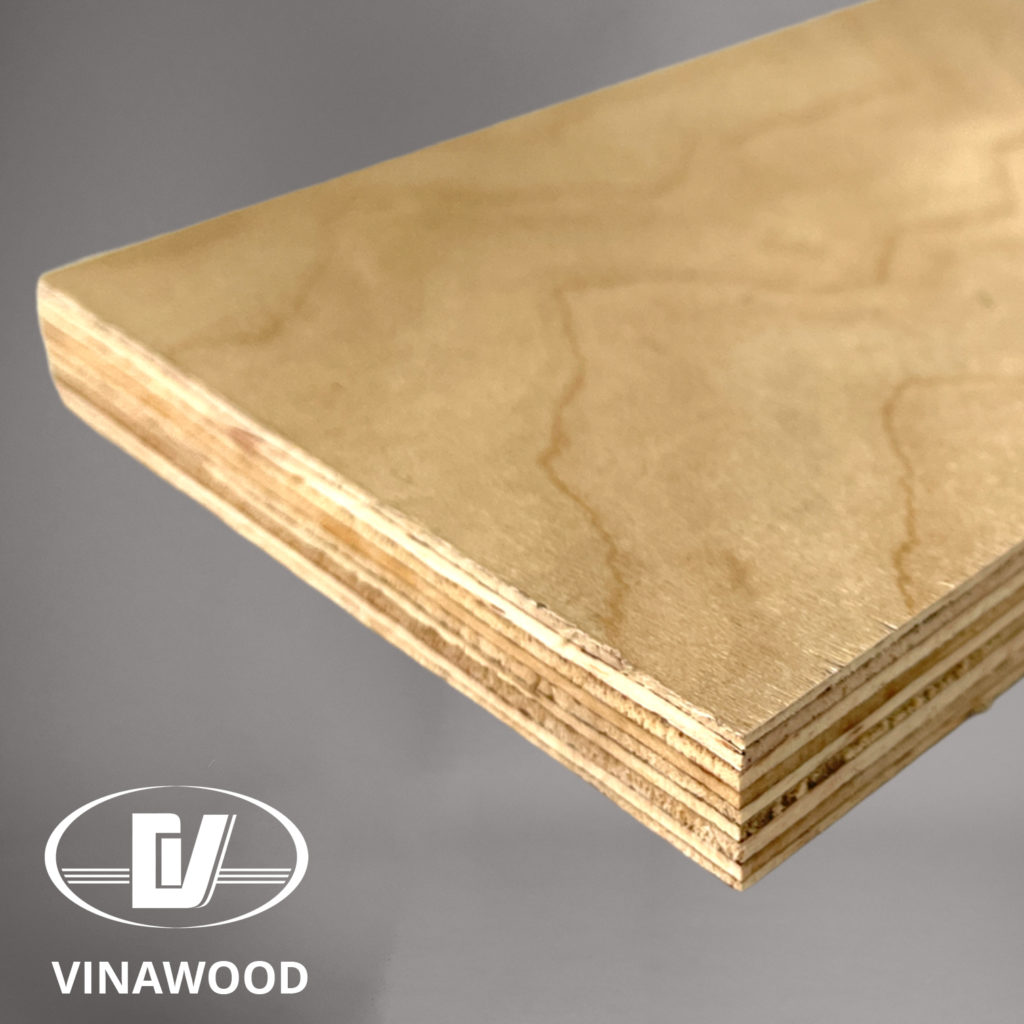

Vinawood’s MDO 1SF: The Premium Choice

In response to the limitations of the MDO 1S, Vinawood rolled out the MDO 1SF. This enhanced MDO plywood variant retains the formidable strength and durability of the MDO 1S, but incorporates a film backer to increase resilience against environmental factors.

Unpacking the MDO 1SF Technical Specifications

Similar to the MDO 1S, the MDO 1SF is available in standard 4×8 sheets with a thickness of 3/4 inch. Yet, its film backer sets it apart, offering an additional layer of fortification against warping, swelling, and twisting, and consequently improving the overall lifespan of the plywood.

MDO 1SF also maintains a density in the range of 500-650 kg/m3, comparable to the MDO 1S. However, the addition of the film backer significantly enhances its ability to resist moisture and prevent warping, twisting, and swelling.

MDO 1S vs. MDO 1SF: The Verdict

When comparing the MDO 1S and MDO 1SF, each has its unique merits. MDO 1S offers a cost-effective solution with superior performance compared to regular MDO plywood, making it an excellent choice for projects with tight budgets. On the other hand, the MDO 1SF, with its added film backer, provides an additional layer of security and resilience, making it worth the slightly higher investment.

While MDO 1S can handle most tasks adequately, MDO 1SF offers a distinct advantage for projects requiring a higher degree of weather resistance and dimensional stability. So, if long-term value is the primary concern, MDO 1SF emerges as the clear winner.

MDO Plywood mentioned in the article

Conclusion

Vinawood’s MDO plywood variants both outperform many competing products. However, when balancing cost against value, the MDO 1SF stands out as the undisputed champion, making it an ideal choice for consumers seeking the best MDO plywood. Trust the experts; trust Vinawood.