Is plywood a good option for cabinets and furniture?

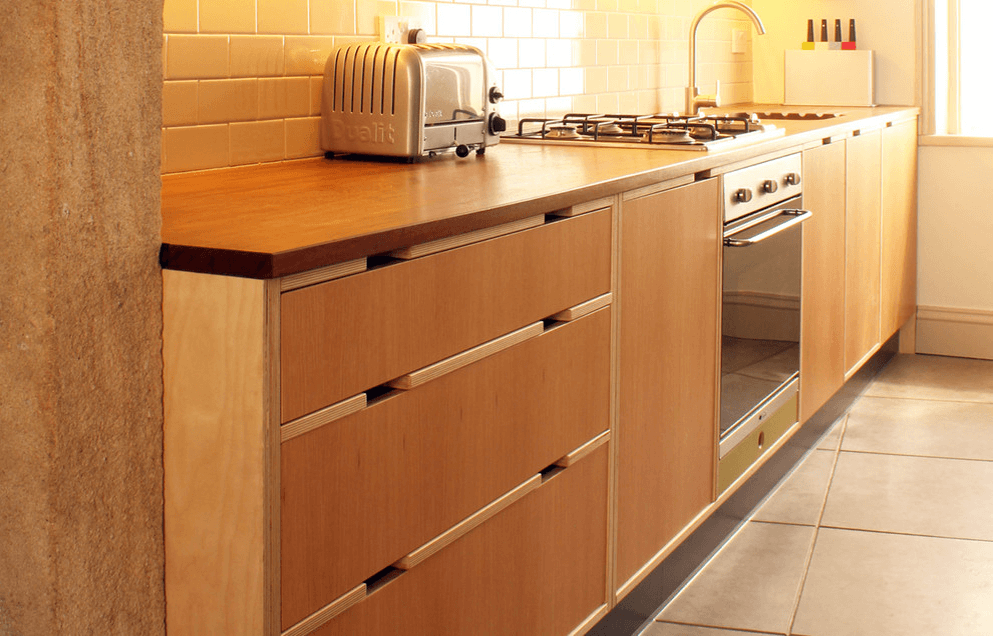

Yes, plywood can be an excellent option for cabinets and furniture for several reasons:

- Strength and Durability: Plywood is made by gluing together thin layers of wood veneer, with the grain of each layer perpendicular to the adjacent layers. This construction gives plywood great strength and stability, making it less prone to warping or cracking compared to solid wood.

- Cost-Effectiveness: Plywood is often more affordable than solid wood, making it a cost-effective choice for large-scale projects like cabinets and furniture.

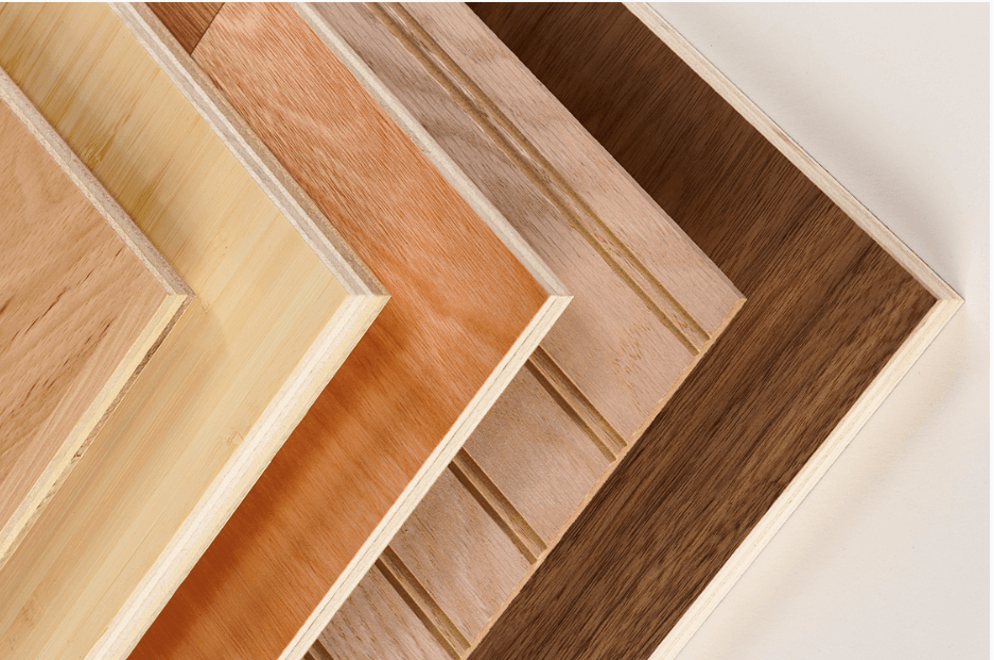

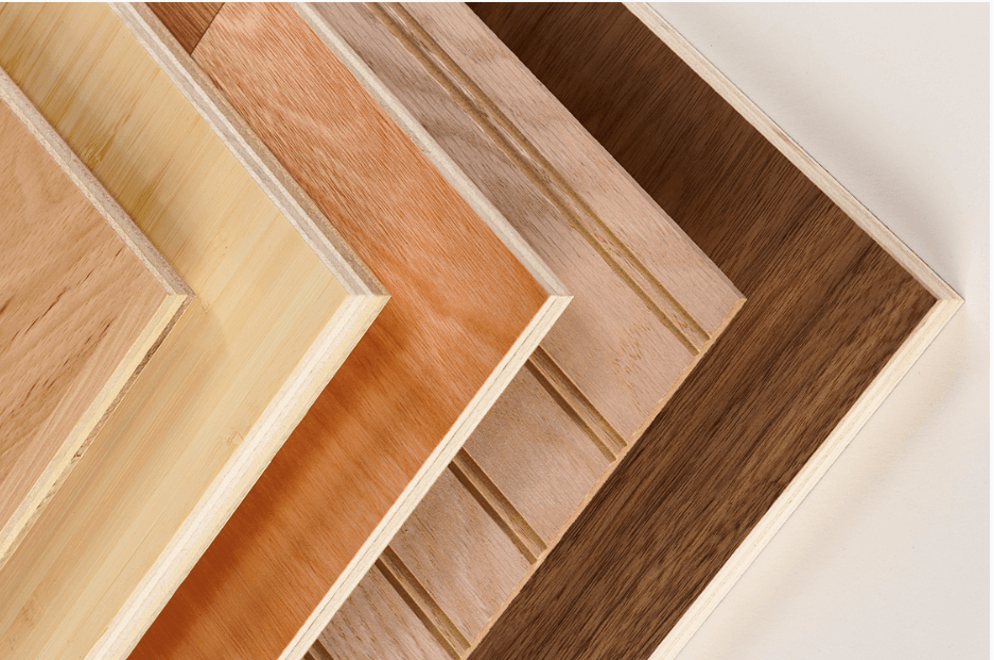

- Variety of Grades and Finishes: Plywood comes in various grades, ranging from construction-grade to furniture-grade. You can choose the grade that best suits your needs and budget. Additionally, plywood is available in different finishes, including plain, veneered, or laminated, offering versatility in design options.

- Consistency: Unlike solid wood, plywood has uniform strength and appearance throughout the sheet, reducing the risk of defects such as knots or voids that can affect the structural integrity of the finished product.

- Environmental Sustainability: Plywood is often manufactured from sustainably sourced wood, making it an environmentally friendly choice for conscientious consumers.

Tips for selecting plywood for furniture and cabinets

There are several types of plywood to pick from. But many of these aren’t suited for furniture and cabinet use, this leads to a cabinet that is weak, prone to warping, or unsightly. Choosing wrong plywood can also lead to mold growth and deterioration over time, while plywood is not strong enough can cause the cabinet to collapse under the weight of heavy items. So when selecting plywood for cabinets, there are several factors to consider:

Durability and Strength

Plywood is designed to withstand heavy loads and resist warping so it is the best choice for cabinets.

Grain pattern and Color

This factor can impact on the appearance of the finished cabinet, plywood which has a more uniform pattern is often preferred for cabinets that will be painted, while plywood with a more distinctive grain pattern is ideal for cabinets that will be stained or finished with a clear coat.

Moisture Resistance

Cabinets which are in areas with high humidity such as kitchen and bedrooms, should be made from moisture-resistant plywood to prevent damage from water and mold.

Sustainability

Plywood made from sustainably harvested wood is an environmentally friendly choice that helps to preserve the world’s forest.

Budget

The cost of plywood can vary wisely, so it is important to select a plywood that fits within yoru budget without sacrificing quality.

Which plywood varieties are best suited for cabinets?

In addition to facial evaluations, the quality of commercial-grade plywood is also determined by the type of core used in its manufacture. Depending on the producer, various core types are available, each with unique features and attributes.

For cabinets, plywood varieties that are commonly preferred include:

Hardwood plywood

Hardwood plywood is made from hardwoods, as its name suggests. Oak, maple, and birch are some of the woods that are used. This plywood tends to be the heaviest of all the plywood options. It is most often used for furniture or something that requires a frame for load bearing.

Plywood panels

Plywood panel is pre-cut and ready to use boards that are ideal for DIY projects. They can be various types of ply and wood.

Sanded plywood

Sanded plywood has plies on the top and bottom that are sanded during the manufacturing process. This type of plywood is ideal for items that can be seen, such as shelving, paneling, and cabinets.

Structural plywood (plywood sheathing)

Structural plywood is intended for permanent fixtures and structures. It is affordable but strong. It is not finished and is best used in places that will not be seen. Another material, such as flooring should cover it. It is also used for framing, bracing, and beams.

Also, you should consider plywood core types for your cabinet

- Veneer center (V/C)

This is the standard compressed wood center, with an odd number of layers of the facade, laid at 90-degree points to one another. The real number of layers can extend somewhere in the range of 3 to 11, contingent on the thickness of the pressed wood sheet and the nature of the compressed wood.

As a rule, the more layers, the greater the pressed wood is viewed as. One hazard with facade center pressed wood is that flaws can occur without much of a stretch “transmit” to the face layer, appearing as spaces or stains in the completion. This is particularly obvious with a slim face facade.

- Fiber core (MDF)

The whole center is a solitary medium thickness fiberboard (MDF). This will, in general, produce the steadiest board. The board is incredibly machine able without any voids. The fiber core’s smooth surface gives a better center than the completion of the face and back facade. The main disadvantage of MDF is its high weight.

- Pro–Core

Another “supportive of center” is accessible from certain makers. This consolidates layers of hardwood facade, with layers of MDF. In doing as such, it includes an auxiliary quality that the MDF is missing, while at the same time keeping the smooth, level surface of the MDF for the facade to be stuck to. The facade centers will be towards within, with the MDF layer just beneath the face facade.

- Particleboard Core (PBC)

This is like MDF, except for having a particleboard center, rather than MDF. Like the MDF, PBC gives an amazingly smooth surface to the facade’s wrapping up. Nonetheless, it is not even close to as solid as MDF.

- Lumber core (LBC)

This is a five employee development, with two flimsy facades (the face facade and one reinforcement layer) on either side of the wood center. The center is made of a progression of edge-stuck portions of timber, extending from 1-1/2″ to 2″ in width.

This sort of center is just found in hardwood pressed wood that is 3/4″ thick or thicker. It gives a compressed wood that is amazingly impervious to clasping, winding, and distorting.

While the facade center is the most regularly discovered center utilized in the cabinet grade plywood supplier, the steadier a center is, the higher an evaluation it is viewed as. In this manner, the fiber core and particleboard center are really viewed as the most excellent bureau pressed wood. This quality, obviously, reflects in the cost of the compressed wood, yet it accommodates a superior completed item.

What plywood thickness is recommended for cabinets?

In generally fabricated face-encircled cupboards, the edge offers significant auxiliary help. This permits slenderer and less steady materials to be utilized in the bureau inside. Today, patterns and inclinations are changing, and more mortgage holders lean toward frameless cupboards, which require an alternate kind of bureau development and more vigorous materials.

While cabinet grade plywood is accessible in sizes from one-eighth-inch and up, numerous fabricators favor local ANSI HP-1 ostensible three-quarter-inch boards for its strong properties.

These boards can be utilized without supporting or nailing on the backs and sides of the bureau—these outcomes in a significant, frameless bureau box that can be hung direct-to-stud with no spikes. Cabinet grade plywood suppliers make sure that the thickness is perfect and just what the customer demands.

As far as the thickness you need, that will depend on what you’re building. For example, you may use ¾″ plywood–things like side panels, bottom panels, shelving, etc. But you should use ¼″ plywood for drawer bottoms, door panels and cabinet back panels.

People often ask about using ½″ instead of ¾″ plywood to save a little money. And in some cases, you can swap them. But not in every case. You can almost always use ¾″ material in place of ½″. But you can’t always use ½″ in place of ¾″. So ¾″ plywood is much more versatile and can be used for most any situation. Maybe, in some cases, it’s a little overkill.

The price difference between ½″ and ¾″ plywood isn’t really that much (maybe $10-15). However, you’ll need to buy different size pocket hole screws, edge banding, nails, etc. for ½″ vs ¾″ plywood.

So in the end, you’ll have to stock a bunch of different supplies for each size which adds to the cost. So the savings is minimal, but you’re losing structural strength in the process. That’s not a trade I’m willing to make.

Where to buy cabinet grade plywood?

Depending on your location and what options you have around you, there are lots of places to potentially buy plywood.

Many stores have a wide variety of plywood options, but because they’re catering to builders, their cabinet grade plywood options are usually pretty limited.

You may be able to find some of the more common options on the shelves–like birch, maple, or oak. But if you can’t find hardwood plywood there, they usually at least carry sanded plywood and can often order some specialty options, too.

Another option is your local building supplier. Many times these local suppliers may not keep hardwood or sanded plywood well stocked, but they can often order it for you if they don’t have it on their shelves.

If you’re fortunate enough to have a hardwood lumber supplier locally who sells plywood, you can likely find some really nice, high end or specialty plywood there. But since we don’t have anything like that where I live, I don’t have a lot of advice to share about buying it that way.

Vinawood is a prestige supplier from VietNam,established in 1992. VINAWOOD specializes in producing Film Faced/Formwork Plywood, Commercial Plywood, Furniture Plywood, and wholesaling office furnitures.Being on the lead and favored by the majority of foreign markets in Asia Pacific, in 2012, VINAWOOD took a leap forward on production standards and started exporting to North American, Latin American markets (the U.S.A, Mexico), and Middle Eastern markets (Turkey, the U.A.E.). In 2014, VINAWOOD established Domestic Sales Department to serve trading and construction needs in Vietnam.

This is the place that your can consider buying plywood for your project. Plywood is too pricey for you to not be picky about it. Make sure you take your time to look it over well before adding it to your cart.

MDF and plywood cabinets, which is better?

If you’re torn between plywood and MDF cabinets for your home, it’s important to understand the differences in composition, strength, appearance, and cost to make an informed decision.

Both materials have their own distinct qualities, and the choice largely hinges on your requirements, budget, and design preferences. Here’s a breakdown of the advantages and disadvantages of plywood versus MDF cabinets to help you decide which is best for your kitchen renovation.

Plywood and MDF are both derived from wood, but their manufacturing processes set them apart. Plywood cabinets consist of layers of wood pressed together, with each layer oriented in alternating directions for exceptional strength. On the other hand, MDF, or medium-density fiberboard, is created by transforming wood fibers into pulp, combining them with resins, and subjecting them to high pressure and heat to form a solid board.

The distinction between plywood and MDF is noticeable in their appearance and texture. Plywood retains a visible wood grain pattern due to its layered construction, while MDF boasts a smoother, flatter surface without any discernible wood grain.

The choice between plywood and MDF depends on the specific requirements of your project, such as whether you prefer painted or stained cabinets. Plywood offers superior durability, making it a worthwhile investment for cabinets that will withstand heavy use over time. Meanwhile, MDF is more budget-friendly and provides a smoother surface for painting and applying veneers.