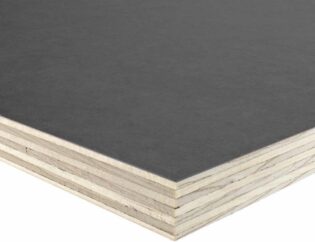

Vietnam is widely respected for the high-quality plywood its manufacturers produce. Among the top plywood suppliers in Vietnam, Vinawood, a leading Vietnam film faced plywood manufacturer, is particularly distinguished for its superior phenolic plywood products.

Known as Film Faced Plywood or Phenolic Faced Plywood, these products are vital to the construction industry. As one of the leading plywood manufacturers in the USA and around the world, Vinawood offers a range of products to cater to various project requirements. From the robust 3/4 ply and APA rated sheathing to versatile 4×8 sheets and 5×10 plywood sheets, Vinawood is the go-to choice for many plywood dealers.

In this guide, we share tips on how to stock, handle, and use Vinawood’s Film Faced Plywood to maximize its lifespan. Whether you are a plywood dealer or a customer, these guidelines will be valuable in maintaining the quality of your plywood.

1. Stocking Vietnam Film Faced Plywood:

Proper storage of Film Faced Plywood begins as soon as it arrives at your facility or worksite. Here’s how you can ensure it stays in the best condition:

- Store Indoors: Despite being water-resistant, it is optimal to store Film Faced Plywood indoors to keep it as dry as possible and prolong its life. Excessive moisture exposure can weaken the plywood over time.

- Use Flat Pallets: Storing Film Faced Plywood on flat pallets made of appropriate materials helps maintain the quality of the plywood. These pallets should provide adequate support to the entire plywood surface, preventing sagging and maintaining the sheets’ flatness. Ensure the pallets themselves are stored on a level surface.

- Keep It Flat: Always store Film Faced Plywood flat on a level surface. Avoid leaning or propping it up against walls, which can lead to warping or bending.

- Protect the Edges: The edges of the plywood are most susceptible to damage. Using protective materials such as foam or rubber can help safeguard these areas.

2. Handling Vietnam Film Faced Plywood:

Proper handling of Film Faced Plywood can significantly enhance its longevity. Keep these guidelines in mind:

- Lift, Don’t Drag: Always lift the sheets rather than dragging them, which can cause scratches and damage to the surface.

- Two-Person Job: Given the size and weight of the plywood sheets, it’s advisable to have two people handle them to prevent accidental drops and damage.

3. Using Vietnam Film Faced Plywood on Sites:

To maximize the lifespan of Film Faced Plywood on a construction site, follow these best practices:

- Use the Right Tools: Always use sharp, high-quality cutting tools to prevent splintering or rough edges.

- Cleaning: After each use, clean the plywood to remove any residues that could affect its durability. Use a mild cleaning solution and a soft cloth.

- Regular Inspections: Regularly inspect the plywood for signs of damage or wear. If the surface film is damaged, it can be repaired with a phenolic resin filler to maintain its water resistance.

Concrete Pouring Practices with Vietnam Film Faced Plywood:

When utilizing Film Faced Plywood for concrete work, certain practices can significantly enhance the finished product’s quality and the plywood’s lifespan.

- Use a Release Agent: Prior to pouring the concrete, apply a release agent to the plywood. This agent will prevent the concrete from sticking to the plywood, making it easier to remove once the concrete has cured. Using a release agent also helps protect the plywood’s surface, allowing for multiple reuses.

- Avoid High Impact: While pouring the concrete, avoid high-impact practices that could damage the plywood. The force of falling concrete can cause indentation or even cracking on the plywood’s surface. A drop chute or a concrete pump can help control the concrete’s descent.

- Cure Properly: Proper curing of the concrete is crucial. This process allows the concrete to reach its maximum strength and durability. After pouring the concrete, cover it with a sheet or spray it with a curing compound to prevent water loss.

- Remove Carefully: After the concrete has adequately cured, carefully remove the plywood. Avoid using excessive force or prying tools that could damage the plywood’s surface.

- Clean and Store Properly: Following removal, clean off any concrete residue from the plywood using a soft brush and water. Dry the plywood thoroughly before storing it flat in a covered, dry area.

Implementing these concrete pouring practices with Vinawood’s Film Faced Plywood can significantly extend the plywood’s lifespan and result in superior concrete work. As one of the top plywood suppliers and manufacturers in Vietnam and the USA, Vinawood ensures that the quality and durability of your construction projects are uncompromised. Whether it’s 4×8 hardwood plywood, 5×10 plywood sheets, or our resilient 3/4 ply board, Vinawood is your trusted plywood company.

Vinawood, as a leading Vietnam plywood supplier, ensures you have access to the best film faced plywood for your projects. If you’re looking for a plywood distributor near you or a plywood wholesaler for bulk requirements, Vinawood is the name you can trust. As a prominent plywood manufacturer, we ensure all our products meet the highest industry standards. For those asking, “where to buy MDO plywood?”, Vinawood is your answer. Remember, wholesale plywood distributors and suppliers like Vinawood are committed to providing high-quality plywood. So choose wisely, handle with care, and your Vietnam Film Faced Plywood will reward you with longevity and durability.