What is CDX?

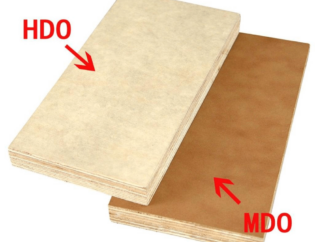

Plywood is made up of thin sheets of veneer that are glued and held together by bonded layers. It is known for its strong resistance to cracking, breaking, or twisting, and is commonly used in construction for its durability. There are different types of plywood available, each with its own classification system divided into the alphabet A, B, C, and D. The classification system affects the price, with Type A and B being the highest priced and best quality, while C and D are more affordable and lower in quality. The number of knots, holes, and defects on the plywood also affects the price, with fewer defects meaning a higher price.

CDX plywood is the most widely available type of plywood on the market. It is made from laminated softwood and is the cheapest option. It is produced in all factories across the country, regardless of size, to serve the construction process. The quality of CDX plywood is low, but it is very strong.

CDX stands for:

C – one side of the board is grade C, which means it has a medium surface quality.

D – the other side of the board is grade D, which means it has small holes and patches.

X – External Exposure glue is used to bind the boards together.

CDX is also known as C-D Exposure Plywood. The letters C and D refer to the quality of both the front and back surfaces of the plywood panel. This means that one side of the plywood is rated C, and the other side is rated D. The “X” indicates that an exterior glue was used in the manufacturing process.

When creating CDX plywood, manufacturers align the wood grain components carefully to reduce shrinkage. CDX plywood is an affordable and convenient laminate that consists of several layers.

CDX Plywood sizes and thickness

After exploring the meaning of CDX plywood, let’s dive into its size and thickness. CDX is a widely used type of plywood and can be found at most hardware stores for DIY and construction projects. The sizes of CDX plywood usually range from 3 to 9, with thicknesses varying from 1/4 inch to 1 1/4 inches. Keep in mind that these sizes are nominal, and you should account for a deduction of approximately 1/32 inch after sanding when considering the thickness of CDX plywood.

What is CDX plywood used for?

Although CXD is not a sustainable option, it is still an ideal choice for construction projects. CDX plywood is used for interior and exterior.

Exterior uses

Outside the home, contractors often use CDX plywood to construct exterior walls and roofs during construction. This is a required part as it is used as additional support under the shingles, under the roofing felt, behind the insulation and siding.

Roof sheathing

CDX is most commonly used to make roof panels. It is known that the quality of CDX plywood is extremely durable, so it is ideal as a construction material for the roof base. In this case, CDX plywood has the durability and water resistance to make it suitable for exterior applications. Additionally, because it is waterproof, CDX will dry very quickly and lose water over time, which helps it return to its original size.

Construction of crates and boxes

CDX is also one of the rare plywood products chosen to make crates and boxes. Dimensional stability and resistance to water damage are also a plus and their solid nature is also an advantage for this.

Interior uses

Inside the home, CDX plywood is used as an additional floor covering just below the carpet pad or as a backing for tiling. In addition, it is also used to serve small utility purposes such as shelves, cabinets or warehouses. While it is not popular for producing beautiful furniture due to its unattractive appearance, it is highly durable and therefore often used to make shelves in garages and factories.

Garage shelves

Although CDX plywood is not the best choice for making shelves because of its unsightly appearance. But it possesses high durability, so CDX plywood is used a lot to make shelves in garages and factories.

Sub-flooring

To reduce curvature and bending, the incredible strength of CDX comes in handy. Plywood is mainly used as a subfloor for ceramic floor finishes such as in kitchens and bathrooms.

How long can CDX Plywood be exposed?

CDX plywood is a versatile material that can be used in various projects, but it has a significant disadvantage in that it cannot withstand harsh weather conditions. Rain and snow are the primary factors that can seriously impact the structural integrity of CDX plywood. CDX Plywood panels have a fully waterproof bond and are designed for applications temporarily exposed to the weather, such as where construction delays may be expected before the provision of protection. It is not uncommon for panels to be exposed to the weather for six months to a year.

The wood grain component in CDX plywood can absorb moisture without warping or rotting. So after a few days, moisture from rain that occurs during a construction project can escape and the CDX plywood dries out but retains its original size and shape. So a few rainy days are not a problem. However, if the project is exposed to rain and snow for an extended period, it will compromise the durability of the CDX.

In short, CDX plywood should not be exposed to severe weather conditions for too long. High humidity can also damage CDX plywood. Additionally, when used in interiors, such as in bathrooms, laundry areas, or other rooms where moisture is common, the composition of CDX plywood must be able to reliably withstand stress.

What Is CDX treated with plywood?

Although CDX plywood has flexible applications, it is also a type of plywood that is easily damaged by the impact of external factors. That’s why manufacturers have introduced measures to preserve the durability and longevity of CDX. These measures will improve the quality of CDX, making it resistant to high humidity and mold. CDX plywood is a type of plywood treated with chemicals to improve the performance and durability of the board. This method is performed by soaking CDX plywood panels in specially formulated synthetic chemicals to better resist moisture and limit mold accumulation.

CDX treated with plywood is also known as CDX-treated plywood or pressure-treated plywood. This type of plywood provides construction projects with a sturdy product that is more durable than untreated CDX plywood. Increased durability will prolong the life of the plywood, which will help the homeowner have less project maintenance, or limit the need to repaint or replace other plywood panels. This will help homeowners save costs and time. This is a big plus when it comes to extending the performance and lifespan of the product. So CDX plywood that has been treated with additional protective qualities is a popular choice.

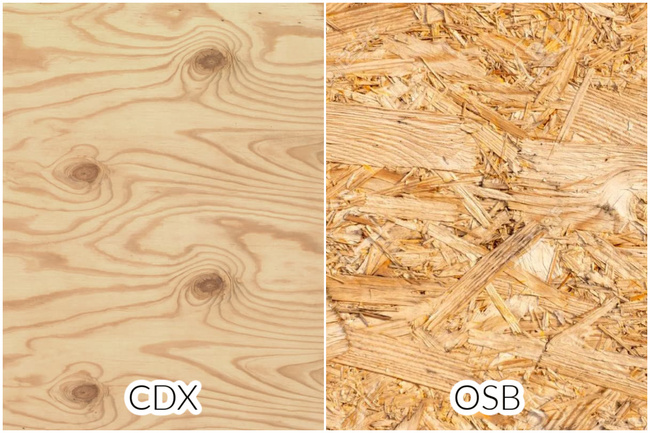

CDX Plywood Vs. OSB: Which is better?

There are many questions surrounding the issue: OSB vs CDX: Which One Should You Choose? These types of plywood are all commonly used in construction projects, but each type has different advantages and disadvantages. Let’s see which type of plywood suits your needs.

OSB stands for Oriented Strand Board, a type of plywood made from wood chips, resin and glue, molded and baked together. OSB is a type of engineered wood panel consisting of rectangular wood fibers, 8 to 15 cm long, arranged in layers in a diagonal direction. These wood fibers are joined together with a waterproof, heat-treatable adhesive.

CDX can withstand higher loads than OSB but its moisture resistance is lower. CDX is durable and is the perfect choice for roofing, floors and low-humidity areas. OSB will have higher moisture resistance and withstand places with average humidity. Although not as strong as CDX, it can be exposed to places with high average humidity. OSB will be popular in wall, floor and roofing applications.

CDX and OSB are both waterproof and cannot withstand frequent exposure to water or steam. Because of its tight structure, no gaps and plastic inside, OSB can withstand moisture for a longer period than CDX. However, OSB still has the phenomenon of changing shape over time when wet. CDX is resistant to low humidity, however, CDX treated with plywood is better, more durable, and has improved termite and rot resistance.

Additionally, OSB is much more affordable than CDX plywood. If you are weighing your costs, choose OSB. It is a perfect choice as it is more resistant to humidity and is cheaper than CDX.

Thus, the above article has answered the question: what is cdx plywood? In addition, VINAWOOD has also provided information to help you choose OSB or CDX plywood. Hopefully this article will help you in the process of choosing the right plywood for your project. If you would like more information about Plywood types, check out our website.