What is a Particle Board?

Particle board, also known as chipboard, is made from wood particles and a binder that is compressed under high pressure and heat. It is a cost-effective and lightweight material that is commonly used for making shelves, cabinets, and other furniture pieces. However, it is less durable and stable than plywood and may not hold up well under heavy use or exposure to moisture.

What is Plywood?

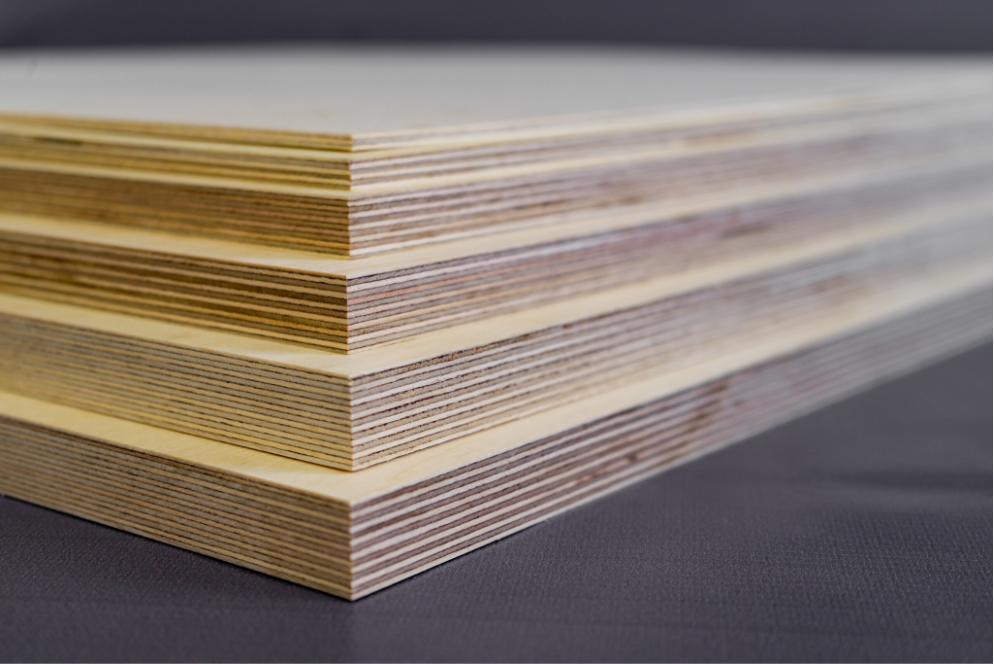

Plywood, on the other hand, is made from thin layers or plies of wood that are glued together with their grains at right angles to each other. This cross-grain construction gives plywood superior strength, stability, and resistance to warping and cracking.

The manufacturing process

Both particle board and plywood are made from a variety of wood species, such as mango, eucalyptus, poplar, and teak. The manufacturing process involves cutting, drying, and milling the wood into particles or veneers, which are then treated with adhesives and pressed into sheets. Particle boards are mixed, compressed, and formed. Plywood is layered, glued, and pressed then heat-cured.

Differences Between Particle Board and Plywood

Durability and strength

When it comes to durability and strength, plywood takes the cake. It can withstand more weight and pressure than particle board and is less prone to breakage. This makes it a better choice for furniture that needs to last for years. Plywood is more resistant to moisture and termites than particle board and can be finished in a variety of ways. It also has a more attractive grain pattern, making it a better choice for furniture used outdoors or in damp areas that need to look good. Particle board is more prone to moisture damage and lacks the aesthetic appeal of plywood.

Moisture resistance

When undertaking projects exposed to significant moisture, opting for plywood over particleboard is advisable. While standard plywood, whether exterior or interior, isn’t entirely waterproof (with marine plywood being the closest), it still outlasts particleboard when faced with moisture. Particleboard tends to swell and expand readily when exposed to moisture, resulting in a substantial loss of strength. Moreover, swollen particleboard becomes heavier, posing additional safety hazards. Therefore, for projects in moisture-prone environments, plywood offers greater durability and resilience compared to particleboard.

Weight

Plywood is constructed using at least three layers of wood arranged perpendicular to each other and bonded with a robust wood adhesive. While the outer layers of plywood typically feature higher-quality wood, the density remains consistent throughout the board’s cross-section. For instance, a medium-quality pine plywood board typically has an average density of 600 kilograms per cubic meter.

On the other hand, particleboard is a form of engineered lumber made from wood chips and particles that are compressed and bonded using urea formaldehyde. Among various types, medium-density fiberboard (MDF) is one of the most common. While MDF may not be structurally strong, it excels as a sheathing material in dry environments. Pine MDF, for example, has an average density of 700 kilograms per cubic meter, though it can be as dense as 1,000 kilograms per cubic meter.

Plywood sheets are also so much lighter than particleboards. They are easier to carry from area to area, or floor to floor. The weight also matters when you’re making a wall cabinet or some furniture with wheels. Being heavier, wall cabinets or wheeled furniture made purely of particleboards could collapse under its own weight.

Aesthetic differences

While plywood is generally stronger, the surfaces of particleboard are usually smoother. That’s because the cross-grain surface of plywood prevents the even distribution of finishing material (like decorative laminates).

One can try to smooth plywood out with sandpaper, but it cannot match the kind of surface smoothness that particleboards can provide. With its smoother surface, particleboard allows decorative laminates and other finish material to make the finished product look more stunning.

Price

Price is one of the main factors that influence the choice between particle board and plywood.

| Parameter | Particle Board | Plywood |

| Raw Material Cost | Lower | Higher |

| Manufacturing Cost | Lower | Higher |

| Price (per square foot) | 0,42 – 0,66 USD | 0,72 – 1,32 USD |

Note: The prices mentioned in this table are subject to change and may vary depending on several factors such as location, brand, and quality.

Particle board is cheaper, but plywood is more durable.

The price of particle board and plywood depends on various factors such as the type of wood used, the manufacturing process, the thickness, and the brand. Higher-quality particle boards and plywood cost more than their lower-quality counterparts.

Despite plywood’s numerous advantages over particleboard, the affordability of particleboard keeps it highly favored among both furniture manufacturers and homeowners. Typically priced at around half or even less than plywood or solid wood, particleboard remains a cost-effective option. Price remains a significant factor in any project involving engineered wood products, making particleboard a popular choice due to its economic appeal.

Pros and Cons of Particle Board vs Plywood

Plywood and particle board are both versatile and cost-effective building materials that are used in a variety of applications. They offer many advantages, however they also have some advantages. Let’s see their pros and cons in this table below:

| Plywood | Particle board | ||

| Pros |

|

|

|

| Cons |

|

Not ideal for heavy-duty use |

Applications of Particle Board and Plywood

Recommended uses for particle board

Now that you’re familiar with its potential, let’s explore the diverse applications of particle board and where it excels. Particle boards, known for their versatility, find utility in various home projects. It’s suitable for false ceilings, wall units, and panels, and serves as the structural core for modular furniture. Notably, it’s a favorite for DIY enthusiasts due to its widespread availability and cost-effectiveness. If you enjoy home improvement projects, particle board can be your preferred choice

Recommended uses for plywood

We’ve discussed plywood’s durability, but let’s explore its ideal home applications. Plywood finds utility in various areas including flooring, wardrobes, cabinets, doors, shutters, and walls. Additionally, it serves well in crafting headboards, footboards, wall panels, and as a framework for upholstered furniture. Enhancements such as bug, fire, mold, and water resistance treatments further elevate its utility.