What Is MDF?

MDF, also known as medium-density fiberboard, is made from wood fibers. Small wood chips or wood fibers will be mixed with wax and resin and then heat-pressed into dense and durable panels. They are made into panels by applying high temperature and pressure. The resulting smooth wood product has no wood grain and has many characteristics similar to particle board.

MDF has a uniform and smooth surface and is available in different thicknesses and weights. Due to its durability and long-lasting nature, MDF is commonly used in furniture making, cabinets, internal shelves of cabinets, and decorative wall panels.

What Is Plywood?

Plywood is made up of thin sheets of veneer that are glued and held together by bonded layers. The process involves peeling thin layers from the logs by rotating them horizontally. The veneer panels obtained from the wood peeling process are cut to the desired size, dried, patched, glued together, then fired in a press at 140°C (284°F) and 1.9 MPa (280 psi) to form a sheet of plywood. Plywood’s structure is made up of many layers placed perpendicular to each other, creating its stability. Even if it expands or contracts due to the impact of external factors, Plywood still retains its original shape, limiting warping. It is known for its strong resistance to cracking, breaking, or twisting, and is commonly used in construction for its durability

There are different types of plywood available, each with its own classification system divided into the alphabet A, B, C, and D. The classification system affects the price, with Type A and B being the highest price and best quality, while C and D are more affordable and lower in quality. The number of knots, holes, and defects on the plywood also affects the price, with fewer defects meaning a higher price.

Plywood can be painted or stained easily, and the characteristics of the wood are also clearly shown on the outside. There are many different designs and uses for plywood, depending on the material you choose.

Applications of MDF and Plywood

Let’s explore the uses of MDF vs Plywood so you can answer your consideration: “Is plywood or MDF more sustainable for your project?”

Applications of MDF

MDF is a versatile material that can be used for a variety of applications. It is sturdy and durable, ideal for use in furniture and cabinets. It is also easy to machine and can be finished to a high standard. MDF board is also moisture resistant, making it an ideal choice for use in bathroom and kitchen environments.

Possessing a smooth and uniform surface makes MDF an excellent material for manufacturing products such as cabinets or other types of furniture that require a smooth surface. In addition, because of its durability and high weight, MDF can also be used to make shelves or objects such as simple drawers and cabinets. MDF also can absorb paint and dyes well, so it can be painted according to the homeowner’s preference and brings high aesthetic value.

For applications such as signs, silhouettes and decorations, MDF is also ideal as a design material. Because MDF is thin, easy to cut, and has a smooth surface that doesn’t require too much sanding, MDF is the perfect material to work with.

It can be said that MDF is a construction product with high flexibility, good durability and affordable price. Because of its consistency, MDF is considered a popular design material in many home and professional projects, including:

- Interior

- Cabinets and shelves

- Floor

- Decorative project

- Speaker box

- Wall paneling

- Doors and door frames

- Construction of fair booths and stages

Applications of Plywood

The endless possibilities of plywood can be used for a variety of purposes. Convenience and lightweight structural durability are the advantages that make plywood the perfect choice for many different uses such as house construction, shipbuilding and aviation DIY birdhouses and garden furniture. Here are a few examples of Plywood’s applications :

- Exterior walls: Plywood is most commonly used to make exterior walls. Plywood is made from hardwood and is highly durable. This makes it an ideal choice for combating the elements. Plywood is also used to provide a layer of structural integrity to the building to protect against potential impacts and help regulate temperature.

- Interior walls: Interior walls are also one of the most popular applications of plywood due to its durability and versatility. Plywood panels are used to preserve the structural integrity of the home’s interior

- Furniture: Plywood is also often used for interior and exterior furniture. Birch plywood is a typical hardwood used to make furniture, from desks, wardrobes, chests of drawers to other types of furniture in the home. Because of its durability, high stability and long lifespan, plywood is very popular in the furniture production process.

- Flooring: Plywood is a perfect choice for applications such as flooring and layered roofing. Plywood has a sturdy structure, good force resistance, and high stability, so it is often used to make floors and roofs. As well as indoor flooring, hardwood plywood is a great choice for outdoor use when it comes to flooring, such as garden flooring.

- Roofing: Plywood is considered the ideal choice for roofing because of its good weather resistance and reasonable cost. Compared to solid wood, plywood is less likely to warp or crack during use, making it a more reliable roofing material.

- Marine-related use: Marine plywood is a type of plywood that is specifically created for use in wet environments and harsh marine weather conditions. While it’s not completely waterproof, it is made with high-quality adhesive and a tight veneer and core structure, which makes it the best choice for shipbuilding and port construction. To minimize gaps between plywood panels, marine plywood is often designed with multiple layers of veneer and core.

- Skate ramps: Baltic birch plywood is the most popular and preferred material for skateboard ramps, thanks to its flexibility and durability. In particular, it is easier to bend into a “U” shape and is smoother than other sheet and wood materials, allowing skateboard wheels to easily roll over slopes.

- DIY: The convenience and durability of plywood make it a popular choice among DIYers. In particular, plywood is significantly lighter than solid wood, making it easier to transport and work on DIY projects.

User-Friendliness

The applications of MDF vs Plywood in terms of user convenience are very diverse.

MDF, with its smooth and easy-to-process properties, is often used in many interior and decorative applications in public or home places. Cutting, drilling and processing details on MDF are easy, helping crafters complete projects quickly and accurately. Additionally, MDF is often painted and coated smoothly, creating an aesthetically pleasing result.

Plywood, with its flexibility and durability, is commonly used in construction and exterior applications. With its ability to withstand pressure and bending, plywood is ideal for creating structures and furniture of complex shapes. In addition, painting, coating or animating the plywood surface is also very easy, helping users create finished products with beautiful appearance and high quality.

In conclusion, both MDF vs Plywood bring convenience to users through easy processing and adaptability to many different types of applications in many fields

Plywood vs. MDF Comparison

MDF vs Plywood both have advantages, but they are used for different projects. In each project, you will find is plywood or MDF more sustainable. Both have strengths and weaknesses based on their build. To help you decide between them, VINAWOOD will compare their main differences in the aspects below so you can choose the one that suits you best.

Durability and Strength

Plywood has higher durability and strength than MDF. Because the veneer layers are tightly bonded together, Plywood is very stable. It will not expand, contract or warp, even under extreme temperatures. On the other hand, MDF is made from wood chips, it is softer and tends to crack when subjected to great pressure. In addition, plywood also has higher flexibility than MDF so it can be easily bent to create curves during the manufacturing process without sagging or breaking. If you are wondering about mdf vs plywood strength, choose plywood

Ability to Hold Screws

Plywood is better able to hold nails or screws than MDF. If you’re planning to use a lot of screws or nails in your project, then plywood would be the most suitable choice for you. This is because MDF is not as strong as plywood and cannot hold screws or nails as well. Plywood is known for its durability and is considered the best option for holding screws or nails. However, if you plan to insert screws or nails into the edge of the wood, be aware that plywood is more prone to break at the edges than MDF.

Resistance to Termites

In terms of termite protection, both plywood and MDF can resist termite attack. MDF, which is made from tightly compressed wood particles and glue, is generally less susceptible to termite attack because the manufacturing process eliminates or minimizes the presence of voids or potential hazards. However, if the surface of MDF is damaged or damp, especially in humid environments, it can still become a target for termites.

Plywood, with its tight plywood layer structure, is also relatively resistant to termites. The discreetness of veneers and water-resistant glue often prevents termites from penetrating inside the material. However, if there is any damage to the surface of the plywood, especially at points where the glue or veneer is broken, termites can find their way in and cause damage.

Moisture Resistance

Plywood resists moisture better than MDF. MDF cannot withstand humidity, when humidity increases slightly it will swell. If you install MDF in an environment with prolonged exposure to water, this environment will reduce the durability of the product. MDF, made from tightly pressed wood particles and glue, is typically less water-resistant than plywood because the manufacturing process eliminates or minimizes the presence of pores.

Plywood, with its tight plywood structure, is often more water resistant than MDF. Water-resistant veneers and adhesives often prevent water from penetrating the material, making plywood better able to withstand wet environments. However, it should also be noted that if the surface of the plywood is damaged or the glue is broken, its water resistance will also be affected.

Effects on Human Health

In terms of impacting on human health, using Plywood is much better than MDF. MDF, which is made from tightly pressed wood particles and glue, often contains chemical compounds such as formaldehyde, which are used as adhesives during the manufacturing process. Formaldehyde is a toxic substance that can cause health problems such as respiratory irritation, skin allergies and respiratory problems if exposed to high concentrations in interior air.

Although Plywood does not contain formaldehyde like MDF, it can still have chemical compounds from glues and additives used during the manufacturing process. If not processed or used correctly, these compounds can also cause health problems such as respiratory and skin irritation.

Environmental Impact

Plywood is relatively more environmentally friendly than MDF. Cutting MDF will create more sawdust than cutting laminate. Sawdust can harm human lungs and contribute to environmental pollution. Therefore, when cutting MDF, you need to choose a well-ventilated place and wear a mask and protective gear. You should buy plywood that is certified by FSC (Forest Stewardship Council) authorities. This organization will support vetted sustainable products for the market

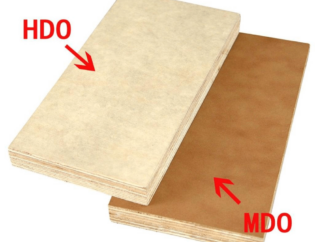

Finish Quality

In terms of finish quality, MDF has a smoother finish than Plywood. However, for high quality plywood, it still has a smooth surface and is highly aesthetic

Load-Bearing Capacity

The load-bearing capacity of MDF and plywood depends on many factors such as thickness, structure, and the specific materials used in the manufacturing process. However, in general, plywood usually has better load-bearing capacity than MDF.

Plywood is made from layers of wood glued together, creating a strong and uniform structure. The tight bond between the wood and veneer layers often creates a material with good load-bearing capacity, suitable for applications requiring durability and stability, such as structural construction and furniture making.

On the other hand, MDF, although it has some load resistance, is usually not designed to withstand heavy loads like plywood. MDF is often used for interior applications that are lightweight and do not require high load-bearing properties, such as making wooden furniture or creating decorative shapes.

MDF vs Plywood can bear loads, such as MDF vs plywood cabinets. However, Plywood generally has better load-bearing capacity and is more suitable for applications that require high stability and durability.

Can MDF replace plywood?

There are many questions about the issue: Can MDF replace plywood? The answer is Yes, MDF (Medium-Density Fiberboard) can indeed replace plywood in many applications (such as mdf vs plywood cabinets) , but it depends on the specific requirements of the project and the properties of each material.

MDF is a versatile engineered wood product made by breaking down hardwood or softwood residuals into wood fibers, often combined with wax and a resin binder. It’s dense, smooth, and uniform, making it an excellent choice for indoor projects like cabinets, furniture, shelving, and decorative molding. Its consistent surface allows for easy painting, veneering, or laminating.

However, plywood, made by gluing together thin layers of wood veneer, offers strength and durability, especially in load-bearing applications. It’s suitable for both indoor and outdoor projects, including construction, flooring, roofing, and structural sheathing. Plywood’s layered structure provides excellent strength-to-weight ratio and resistance to warping and cracking.

While MDF can replace plywood in many non-structural applications where a smooth and consistent surface is desired, plywood remains preferred for applications requiring structural integrity and load-bearing capacity

In conclusion, while MDF can serve as a substitute for plywood in certain applications, particularly those where appearance and finish quality are crucial, plywood remains indispensable for structural and outdoor projects due to its strength and durability.

Is MDF cheaper than plywood?

MDF is usually cheaper than plywood. MDF is often a budget-friendly choice for many projects. The raw materials used in MDF production, such as wood waste and residuals, are generally more readily available and less expensive than the high-quality wood veneers required for plywood.

MDF vs Plywood, So Which One is Best?

Let’s face it, if there was actually a clear winner in the MDF vs Plywood debate the competitor wouldn’t exist. Both exist to fill their own niches, after all. In the end, the takeaway is this: MDF is better for detailed projects, furniture, and some internal construction. Plywood is better left for construction work that takes advantage of its increased strength while avoiding finer work that requires a lot of finishing.

The above article has provided you with information about MDF vs Plywood. VINAWOOD has also helped you answer the question: Is plywood or MDF more sustainable? Check out our website if you want more information about plywood types