If you’re unsure about the plywood size needed for your upcoming project or if you’re not familiar with the available options, don’t worry. We’ll explore different sizes, thicknesses, and lengths to help you make a well-informed choice. Additionally, the specific type of plywood you require will be considered to ensure suitability for your project.

By the end of our discussion, you’ll have a clear understanding of plywood sizes, thickness, allowing you to proceed with your purchase confidently and start your project smoothly

How is Plywood made?

At Vinawood, we manufactured plywood carefully step by step. Firstly, Plywood is made by peeling thin sheets of wood from a log, then gluing them together in layers with their grains perpendicular to one another. This cross-grain construction gives plywood its strength and durability. After the veneers have been peeled, they are sorted by size and quality. The veneers are then clipped into uniform widths and laid out in a sequence to form a panel.

The next step is to glue the veneers together using a hot press. The glue can vary depending on the intended use of the plywood and can use a cheaper, non-waterproof glue. The hot press applies heat and pressure to the veneers, bonding them together into a solid panel.

Once the plywood is bonded, it is trimmed to its final size and sanded to remove any rough spots. The final step is to grade the plywood based on its appearance and quality. The grading system varies depending on the location but generally, it ranges from A to D, with a being the highest quality and D being thow lowest.

Plywood Core Types

Not all plywood cores are identical. The plywood core, situated between the outer wood veneers, varies in composition.

Different types of plywood utilize distinct cores to manage costs, enhance strength, or improve flexibility, catering to specific project needs. Typically, a veneer core suffices for most projects and is readily available at most home improvement stores.

Regardless of the core type, these panels always feature an exterior wood veneer, creating the impression of a single solid wood sheet:

Veneer Core

This is the most common type of plywood core, which consists of thin sheets of wood (veneer) glued together at opposing wood-grain angles on the same plane for increased strength.

For high-end applications or projects that will leave the laminated edges exposed, look for Baltic B-birch plywood or hardwood veneer plywood.

Veneer core plywood commonly has either 5 or 7 sheets of veneer. For stronger sheets less resistant to bending and warping, purchase 7-ply sheets. Some sheets used in heavy-duty applications can have as many as 13 ply or more.

Lumber core

This consists of edge-glued strips of wood with a wood veneer. This results in a stronger product that resists deflection (doesn’t bend easily), which makes it great for long shelves. It is more expensive and can be hard to find.

MDF core

Not common for home construction, medium-density fiberboard (MDF) is commonly used in art projects and speaker boxes. It is heavy and has a uniform thickness, size, and appearance.

Particleboard core

This is the least expensive plywood core. It isn’t very strong and is susceptible to water damage. It’s best for inexpensive furniture and projects where strength isn’t required.

Importance of Understanding Plywood Dimensions

The thickness of plywood is incredibly important as it directly affects the kinds of things you can build. Let’s take a look at some of the plywood sheet options available and how their thickness contributes to their quality and applications.

Project Suitability

Knowing the dimensions helps ensure that you choose plywood that is appropriate for your project. Whether you’re building furniture, constructing a house, or crafting smaller DIY items, selecting the right size plywood is essential for achieving the desired results.

Cost Efficiency

Purchasing the correct size of plywood minimizes waste and saves money. By accurately estimating the required dimensions, you can avoid buying excess material that will go unused.

Ease of Handling

Being familiar with plywood dimensions makes transportation and handling more manageable. Knowing the size and weight of the plywood sheets allows for proper planning and facilitates smooth logistics during construction or renovation projects.

Structural Integrity

Understanding the dimensions ensures that the plywood fits seamlessly into the intended space without the need for excessive cutting or modification. This promotes structural integrity and stability in the final product.

Compatibility with Standards:

Many construction standards and building codes are based on standard plywood dimensions. Having this knowledge ensures compliance with regulations and facilitates smooth inspections and approvals.

Optimal Design

When designing a project, knowing plywood dimensions allows for precise calculations and layouts. This enables efficient use of material and helps achieve the desired aesthetic and functional outcome.

Standard Sizes of Plywood

The standard sheet of plywood measures 4 x 8 feet. However, it can come in a variety of different thicknesses, so not all standard plywood sizes are the exact same.

Common Plywood Dimensions

Plywood is most often sold in 4′ x 8′ sheets, but may also be available in 4′ x 10′, 4′ x 12′, or 2′ x 4′ sheets. Hardwood plywood (e.g. birch, maple, oak, cherry, etc.) is often available in 4′ x 8′, 5′ x 5′, and 2′ x 4′ sheets.

Softwood plywood may be thicker than hardwood plywood, due to the need for additional plies to lend stability and structure to the sheet.

MDF, or medium-density fiberboard, is another sheet good that is sold in 4′ x 8′ sheets. Usually, the actual dimensions of an MDF sheet are oversized by one inch, and the full sheet is typically 49″ x 97″.

You can use a plywood calculator to estimate the number of 4′ x 8′ sheets needed for a project.

Plywood is usually sold by the sheet, but in some rare cases, it may be sold by the board foot. Board footage is a measure of the volume of wood in the sheet, and to calculate it, you can use a board footage calculator or calculate the cubic inches and divide by 144.

One board foot is the measurement of 144 cubic inches, or 12″ long by 12″ wide by 1″ thick.

Plywood sheets are economical for the pocket as they can be produced to precise dimensions as per the requirement. The commonly manufactured and sold plywood size in India is 2400 x 1200 mm (8’x4’). Other plywood sizes available are 6’x3’, 7’x3’, etc. These are also available in the market.

According to ‘Indian Standard, IS: 10701:2012’ (Structural Plywood — Specification) and ‘IS: 303:1989’ (Plywood for General Purposes Specification), here we have summed up some standard plywood sizes which are available in India in square feet as well as its corresponding value in mm.

- 8′ x 4′ (ft) – 2400 x 1200 (mm)

- 8′ x 3′ (ft) – 2400 x 900 (mm)

- 7′ x 4′ (ft) – 2100 x 1200 (mm)

- 7′ x 3′ (ft) – 2100 x 900 (mm)

- 6′ x 4′ (ft) – 1800 x 1200 (mm)

- 6′ x 3′ (ft) – 1800 x 900 (mm)

In other countries like USA, Canada, UK, etc. plywood is available in different sizes. According to the Canadian Wood Council, plywood is manufactured in prevailing sizes:

- 8′ x 4′ (ft) – 2440 x 1220 (mm)

- 9′ x 4′ (ft) – 2740 x 1220 (mm)

- 10′ x 4′ (ft) –3050 x 1220 (mm)

- 7.8′ x 4′ (ft) – 2400 x 1220 (mm)

- 8.2′ x 4′ (ft) – 2500 x 1220 (mm)

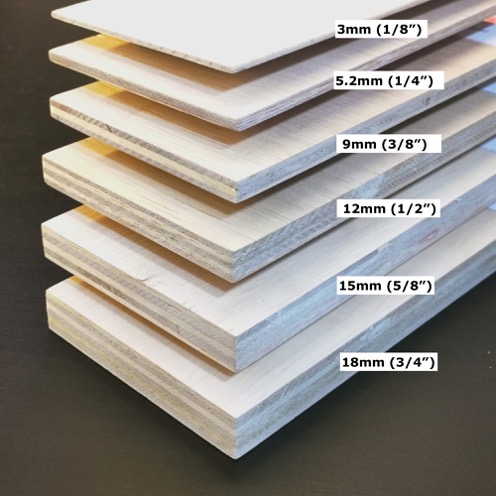

Thickness of Plywood (Plywood thickness chart)

Plywood sheet goods are available in various thicknesses and sizes and are typically sold by their nominal thickness, as well as by the number of plies – 3 ply and 5 ply being common. While the length and width are often the actual dimensions, the nominal thickness is usually different from the actual thickness.

| Nominal | Actual |

| ⅛ inch | 7/64 inch |

| ¼ inch | 7/32 inch |

| 3/7 inch | 11/32 inch |

| ½ inch | 15/32 inch |

| ⅝ inch | 19/32 inch |

| ¾ inch | 23/32 inch |

Size Tolerances

Plywood is often sold in 1/4“, 1/2“, or 3/4” nominal thicknesses, but the actual thickness is often 1/32” thinner. Because the actual thickness may vary, measuring the plywood sheet using a caliper is the only accurate way to determine its thickness.

- A 3/4” sheet is actually 23/32” thick.

- A 1/2” sheet is actually 15/32” thick.

- A 1/4” sheet is actually 7/32” thick.

The exception to this rule is plywood sheets that are over an inch thick. 1-1/4″ and 1-1/8″ plywood sheets are generally true sizes and not nominal. This may vary by manufacturer, though, so always check if you need a precise size or measurement.

Keep in mind, that while many sheets of plywood are also sold by the number of plies, that veneers and plies can have different thicknesses as well, depending on the type of wood used. So, a 3 ply sheet – one of the most common – may measure 2mm or 3mm in thickness, depending on what wood was used in its manufacturing.

It is important to keep in mind, that regardless of the thickness of the sheet, that the more plies it has, the stronger it will be. Therefore, a multi-ply sheet with 9 plies that measures a nominal 3/4″, will be stronger than a sheet with 5 plies that also measures 3/4″.

For some applications, such as sheathing a roof, the 1/32” difference is not important, but for fine carpentry, it may be critical to get grooves and cuts to be precisely the thickness of the plywood.

For example, a groove for a cabinet door panel needs to be the exact thickness of the plywood, or the door will not be stable due to the loose fit of the parts, and it will likely rattle each time it’s opened or closed.

Precision is important for trim carpentry as well; when installing wainscoting panels, if a cut doesn’t match the exact plywood thickness the final result will have noticeable gaps.

Likewise, if you are using plywood as an underlayment, you often need precise measurements of the height of the finished surface. For example, a floor may need to meet up with another material in an adjacent room; you need to know the exact thickness of the underlayment and the material on top to match it with the next space.

Plywood Price

The following are prevailing price of MR grade plywood:

- 4 mm Thick – Rs. 30 to 35 / sq.ft.

- 6 mm Thick – Rs. 38 to 42 / sq.ft.

- 9/10 mm Thick – Rs. 42 to 50 / sq.ft.

- 12 mm Thick – Rs. 45 to 55 / sq.ft.

- 18/19 mm Thick – Rs. 72 to 85 / sq.ft.

The following are prevailing price of BWR grade plywood:

- 6 mm Thick – Rs. 32 to 35 / sq.ft.

- 9/10 mm Thick – Rs. 45 to 50 / sq.ft.

- 12 mm Thick – Rs. 55 to 70 / sq.ft.

- 18/19 mm Thick– Rs. 75 to 85 / sq.ft.

- 25 mm Thick – Rs. 80 to 95 / sq.ft.

The following are prevailing price of BWP grade plywood:

- 4 mm Thick – Rs. 30 to 35 / sq.ft.

- 6 mm Thick – Rs. 40 to 45 / sq.ft.

- 9/10 mm Thick – Rs. 55 to 60 / sq.ft.

- 12 mm Thick – Rs. 60 to 80 / sq.ft.

- 18/19 mm Thick – Rs. 85 to 110 / sq.ft.

The following are prevailing price of flexible plywood:

- 4 mm Thick – Rs. 40 to 45 / sq.ft.

- 6 mm Thick – Rs. 40 to 50 / sq.ft.

- 9/10 mm Thick – Rs. 45 to 50 / sq.ft.

- 12 mm Thick – Rs. 50 to 60 / sq.ft.

The following are prevailing price of fire-resistant plywood:

- 4 mm Thick – Rs. 45 to 50 / sq.ft.

- 6 mm Thick – Rs. 55 to 60 / sq.ft.

- 9/10 mm Thick – Rs. 60 to 75 / sq.ft.

- 18/19 mm Thick – Rs. 120 to 135 / sq.ft.

- 25 mm Thick – Rs. 165 to 175 / sq.ft.

The following are prevailing price of shuttering plywood:

- 6 mm Thick – Rs. 25 to 30 / sq.ft.

- 9/10 mm Thick – Rs. 40 to 45 / sq.ft.

- 12 mm Thick – Rs. 45 to 55 / sq.ft.

- 18/19 mm Thick – Rs. 60 to 70 / sq.ft.

Why is a 3/4” Sheet of Plywood Less Than 3/4” Thick?

There are a few reasons why the actual thickness of plywood varies. First, wood shrinks as it dries and moisture leaves the wood. This means that a sheet of plywood that started at 3/4” may shrink slightly after manufacturing.

Plywood also uses glue to hold the various sheets together. The amount of glue will swell the wood slightly during manufacturing; it will then shrink as it dries. In addition, plywood comes in many types. A “finish” sheet of plywood, used for surfaces like cabinets or furniture will be sanded. This will remove a small amount of thickness of the material as well.

Another reason for varying plywood thicknesses is the range of manufacturing tolerances. Sheets are available in hardwood or softwood veneers and in varying grades, including sanded and unsanded. These different grades have different manufacturing tolerances and may vary more or less from the 3/4” nominal thickness.

Plywood is almost always thinner than the nominal measurement due to the fact that most tooling in furniture and cabinet factories and manufacturing facilities can accommodate plywood that is thinner than expected but not thicker than expected. For this reason, it is very common to see actual thicknesses on the thinner side and rarely thicker than the nominal measurement.

A 3/4” (19 mm) sheet of plywood is typically 23/32” (18 mm).

It’s not just plywood; the actual size of dimensional lumber is also smaller than the advertised nominal dimensions for this reason as well. In fact, most building materials have nominal measurements for a wide range of reasons.

Some are to accommodate swelling and shrinking of material, while others are factoring in a space that may be left between materials during installation. Because this practice is so common, it’s always a good idea to measure your building materials carefully if you need precise tolerances or clearances in your work.

You can use a tape measure to measure the thickness as shown in the above photo. If you are not experienced, you may measure the wrong thickness.

Conclusion

Plywood dimensions vary depending on factors such as wood type, grade, and intended use. Your specific requirements will dictate the most suitable plywood sizes for your business and supply chain, taking into account the inherent thickness loss during manufacturing.

Plywood is just one aspect of the broader picture of product distribution. With over four decades of expertise, Conner Industries stands as a premier supplier in the packaging sector. We offer both standard and customized pallets across various industries, alongside crates and integrated industrial packaging solutions.

Partner with a supplier capable of optimizing your transportation packaging. Connect with our team of knowledgeable professionals to explore how we can assist you today!