Are you torn between choosing particle board vs plywood for your furniture? In this blog, we’ll break down the differences, suitability, and pros and cons of both particle board and plywood, helping you make an informed decision.

What are Particle Board vs Plywood?outside

Particle board is crafted from a blend of sawdust and adhesives. It is also known as chipboard and is commonly used in furniture making. However, it can swell when exposed to water.

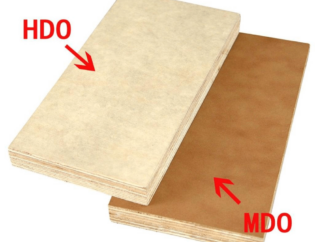

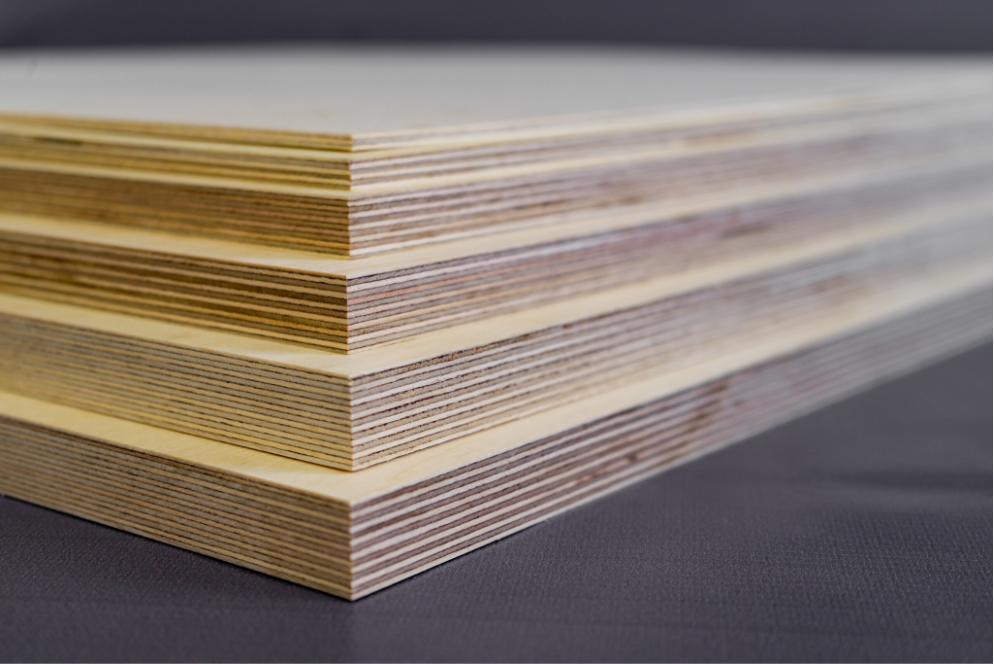

Plywood, in contrast, consists of layers of wood veneers bonded together. It is robust and versatile, used in various furniture items, from sofas to wardrobes. Both particle board and plywood are forms of engineered wood.

Differences Between Particle Board And Plywood

Here are the basic differences between particle board vs plywood:

| Aspect | Particle Board | Plywood |

| Composition | An engineered wood product crafted from wood particles, flakes, or chips. | Manufactured wood product made from layers of thin wood veneer |

| Strength | Typically not as strong as plywood | Stronger because of the cross-grain construction |

| Density | Lower density, resulting in a lighter weight | Higher density, making it heavier in comparison |

| Surface Finish | Smooth and uniform surface, ideal for applying veneers and laminates | Varies; can be smoother than particle board or may display visible wood grain |

| Edges | Prone to chipping and often requires edge banding | Generally has cleaner and more finished edges |

| Moisture Resistance | Prone to swelling and damage when exposed to moisture | Marine-grade plywood exhibits enhanced resistance to moisture, particularly in marine environments |

| Cost | Usually more budget-friendly | Typically pricier, although it fluctuates depending on the wood species and quality level. |

| Application | Frequently employed in furniture making, cabinetry, and shelving. | Versatile; employed in furniture, cabinets, construction, and various other applications. |

| Weight | Less weight, facilitating handling and transportation. | More weighty, imparting a sense of solidity |

| Environmental Impact | Could contain formaldehyde or other adhesives | The eco-friendliness can vary depending on the type of glue utilized. |

| Strength Consistency | The strength is less uniform due to differences in particle arrangement. | Consistently robust because of its cross-grain construction. |

Pros and Cons of Particle Board vs Plywood

Particle board vs Plywood are both versatile and cost-effective building materials that are used in a variety of applications. They offer many advantages, however they also have some advantages. Let’s see their pros and cons in this table below:

| Plywood | Particle board | ||

| Pros |

|

| |

| Cons |

|

Not ideal for heavy-duty use |

How do factors affecting Particle Board vs Plywood price compare?

Cost Comparison:

Particle boards tend to be more economical, while plywood is known for its durability. On average, particle board costs around Rs. 35-60 per square foot, whereas plywood typically ranges from Rs. 50-150 per square foot.

Factors Affecting Price:

The price of both particle board and plywood is influenced by several factors including the type of wood used, the manufacturing process, thickness, and brand. Higher-quality materials generally command a higher price compared to lower-quality alternatives.

| Parameter | Particle Board | Plywood |

| Raw Material Cost | Lower | Higher |

| Manufacturing Cost | Lower | Higher |

| Quality | Lower | Higher |

| Thickness | Thinner: Lower, Thicker: Higher | Thinner: Lower, Thicker: Higher |

| Finish | The cost is influenced by the type and complexity of the finish. | The cost is influenced by the type and complexity of the finish. |

Applications of Particle Board and Plywood

Recommended uses for particle board

Now that you’re familiar with its potential, let’s explore the diverse applications of particle board and where it excels. Particle boards, known for their versatility, find utility in various home projects. It’s suitable for false ceilings, wall units, and panels, and serves as the structural core for modular furniture. Notably, it’s a favorite for DIY enthusiasts due to its widespread availability and cost-effectiveness. If you enjoy home improvement projects, particle board can be your preferred choice

Recommended uses for plywood

We’ve discussed plywood’s durability, but let’s explore its ideal home applications. Plywood finds utility in various areas including flooring, wardrobes, cabinets, doors, shutters, and walls. Additionally, it serves well in crafting headboards, footboards, wall panels, and as a framework for upholstered furniture. Enhancements such as bug, fire, mold, and water resistance treatments further elevate its utility.