Choosing the right type of wood for home building projects is crucial, as it affects performance, durability, and long-term maintenance. Each type of wood has its own advantages and disadvantages, and while CDX plywood might be ideal for one DIY project, it may not be suitable for others. The specific requirements of your home construction project, whether it’s a small bookcase or exterior siding, will determine if CDX plywood is the appropriate choice. In this article, VINAWOOD will help you answer the question: What Is CDX Plywood?

What is CDX Plywood?

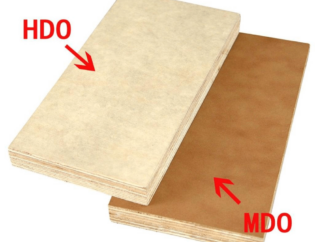

Plywood is classified into different grades, represented by the letters A, B, C, and D. Grade A plywood is the highest quality and most expensive, with the fewest knots, holes, and repaired defects. As the number of these imperfections increases, the quality and price decrease.

So, what is CDX Plywood? CDX plywood has a higher number of knots and defects, placing it in the lower grades. The “C” in CDX indicates that one side of the plywood is of grade C, while the “D” signifies the other side is of grade D. Typically, the better grade side is used on the more visible surfaces, and the lower grade side on less visible ones. The “X” stands for exposure, referring to the type of glue used to bond the plywood.

It’s important to note that the grading pertains to the appearance rather than the quality of the plywood. Despite its lower aesthetic grade, CDX plywood is strong and resistant to damage, making it suitable for applications where durability is more important than appearance.

What is CDX plywood used for?

Although CXD is not a sustainable option, it is still an ideal choice for construction projects. CDX plywood is used for interior and exterior.

Exterior uses

Outside the home, contractors often use CDX plywood to construct exterior walls and roofs during construction. This is a required part as it is used as additional support under the shingles, under the roofing felt, behind the insulation and siding.

Roof sheathing

CDX is most commonly used to make roof panels. It is known that the quality of CDX plywood is extremely durable, so it is ideal as a construction material for the roof base. In this case, CDX plywood has the durability and water resistance to make it suitable for exterior applications. Additionally, because it is waterproof, CDX will dry very quickly and lose water over time, which helps it return to its original size.

Construction of crates and boxes

CDX is also one of the rare plywood products chosen to make crates and boxes. Dimensional stability and resistance to water damage are also a plus and their solid nature is also an advantage for this.

Interior uses

Inside the home, CDX plywood is used as an additional floor covering just below the carpet pad or as a backing for tiling. In addition, it is also used to serve small utility purposes such as shelves, cabinets or warehouses. While it is not popular for producing beautiful furniture due to its unattractive appearance, it is highly durable and therefore often used to make shelves in garages and factories.

Garage shelves

Although CDX plywood is not the best choice for making shelves because of its unsightly appearance. But it possesses high durability, so CDX plywood is used a lot to make shelves in garages and factories.

Sub-flooring

To reduce curvature and bending, the incredible strength of CDX comes in handy. Plywood is mainly used as a subfloor for ceramic floor finishes such as in kitchens and bathrooms.

How long can CDX Plywood be exposed?

Homeowners considering CDX plywood for their next project should understand that it is not suitable for extensive exposure to the elements, as it is not weatherproof. Rain and snow can significantly compromise the integrity of structures made with CDX plywood. However, CDX plywood can endure limited exposure to moisture, including rain and snow.

It is crucial to highlight that the term “limited” is key here. For instance, a few days of rain during a building project should not pose a problem. This is because the wood grain used in CDX plywood production allows it to absorb a certain amount of moisture without warping, splitting, or rotting. Within a few days, this moisture can evaporate, allowing the CDX plywood to dry out and retain its original size and shape.

What Is CDX treated with plywood?

Plywood, particularly CDX plywood, is generally prone to damage from everyday environmental factors. To address this issue, manufacturers have developed a solution that enhances the durability of CDX plywood, making it more resistant to rain, snow, humidity, and mold. CDX-treated plywood undergoes a sophisticated treatment with targeted chemicals that significantly improve the wood veneer’s durability and performance. This is achieved by soaking the CDX plywood panels in synthetic substances specifically designed to resist moisture and mold buildup.

Known as CDX-treated plywood or pressure-treated plywood, this enhanced product offers builders a more durable option compared to untreated CDX plywood. The increased durability extends the lifespan of the plywood, reducing the need for frequent maintenance such as repainting or replacing panels. Homeowners benefit from this added durability, as it minimizes the hassle of ongoing repairs and upkeep. Prolonging the performance and longevity of plywood is a significant advantage in home maintenance, making CDX-treated plywood a popular choice among homeowners and builders alike.

CDX Plywood Sizes, Thickness, & Availability

When planning to use CDX plywood for your next home-building project, it’s essential to understand the available options in terms of size, thickness, and availability. Fortunately, CDX plywood is widely available at most home improvement and garden stores, as it is a popular choice for DIY and construction projects.

Typically, CDX plywood comes in sizes of 3, 5, 7, and 9. The thickness options range from 1/4 inch to 1 1/4 inches, with common thicknesses including 3/8, 1/2, 5/8, and 3/4 inch, readily available in most stores. It’s important to note that the listed thicknesses are nominal, and you should account for a reduction of approximately 1/32 inch after sanding, which is necessary for most projects.

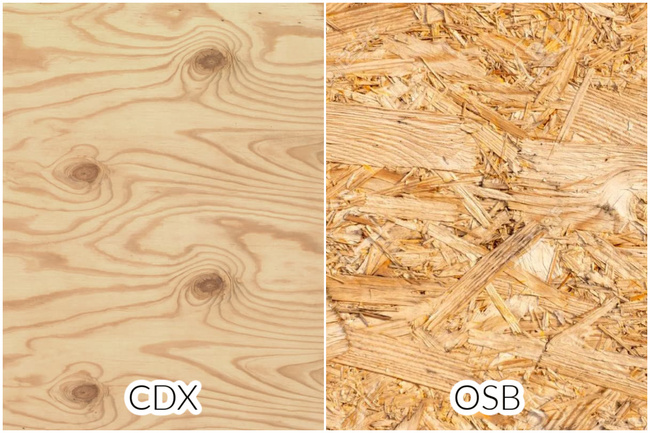

CDX Plywood Vs. OSB: Which is better?

There are many questions surrounding the issue: OSB vs CDX: Which One Should You Choose? These types of plywood are all commonly used in construction projects, but each type has different advantages and disadvantages. Let’s see which type of plywood suits your needs.

OSB stands for Plywood Oriented Strand Board, a type of plywood made from wood chips, resin and glue, molded and baked together. OSB is a type of engineered wood panel consisting of rectangular wood fibers, 8 to 15 cm long, arranged in layers in a diagonal direction. These wood fibers are joined together with a waterproof, heat-treatable adhesive.

CDX can withstand higher loads than OSB but its moisture resistance is lower. CDX is durable and is the perfect choice for roofing, floors and low-humidity areas. OSB will have higher moisture resistance and withstand places with average humidity. Although not as strong as CDX, it can be exposed to places with high average humidity. OSB will be popular in wall, floor and roofing applications.

CDX and OSB are both waterproof and cannot withstand frequent exposure to water or steam. Because of its tight structure, no gaps and plastic inside, OSB can withstand moisture for a longer period than CDX. However, OSB still has the phenomenon of changing shape over time when wet. CDX is resistant to low humidity, however, CDX treated with plywood is better, more durable, and has improved termite and rot resistance.

Additionally, OSB is much more affordable than CDX plywood. If you are weighing your costs, choose OSB. It is a perfect choice as it is more resistant to humidity and is cheaper than CDX.

Thus, the above article has answered the question: what is cdx plywood? In addition, VINAWOOD has also provided information to help you choose OSB or CDX plywood. Hopefully this article will help you in the process of choosing the right plywood for your project. If you would like more information about Plywood types, check out our website.