When’s the Right Time to Stain Pressure-Treated Wood?

So how can you stain pressure treated wood? let’s together with VINAWOOD to find out the 10 steps for staining instructions below, to protect the wood and prevent it from cracking or splitting when the seasons change and have a beautiful space. If you’re wondering whether you can stain pressure-treated wood, it’s important to know when to do it to ensure a long-lasting finish. The best time to stain pressure-treated wood is when it’s dry.

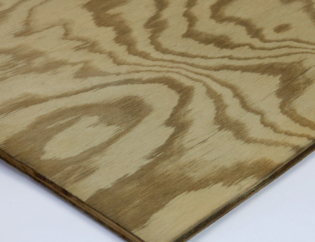

Pressure-treated wood contains chemicals and preservatives, such as micronized copper, that make it more durable and resistant to insects and rot compared to untreated wood. This process uses water to push the chemicals deep into the pores of the wood, so newly pressure-treated wood often has a high moisture content.

To determine when it’s safe to stain pressure-treated wood, you need to check the moisture level. If the wood is too wet, it won’t absorb the stain and the finish won’t adhere well to the surface. You can check the moisture level by sprinkling water on the wood. If the water remains on the surface, the wood is still wet. If the wood absorbs water quickly within 10 minutes, it’s ready for staining.

Humidity levels can vary, so you may need to wait several weeks or up to 6 months before staining pressure-treated wood. Make sure to also pay attention to the weather, as extreme temperatures or direct sunlight can cause the stain to dry on the surface before it properly penetrates the wood. High humidity can also increase drying time. Check the product instructions for optimal weather conditions and plan your project accordingly.

If you can’t wait for the wood to dry, you can buy wood-stamped KDAT (oven-dried after treatment) or ADAT (air-dried after treatment), which can be stained immediately.

A Step-by-Step for Staining Your Treated Wood

So how can you stain pressure treated wood? let VINAWOOD show you 10 steps for staining instructions below, to protect the wood and prevent it from cracking or splitting when the seasons change and have a beautiful space.

Step 1: Picking Out the Perfect Exterior Stain

There are various options available for exterior stains, and it’s important to select the right dye for your project based on your preferences. For outdoor projects, it is advisable to use a dye that includes water repellents and UV stabilizers. The type of stain you choose, be it transparent, semi-transparent, or solid, will depend on your desired final look. Oil-based stains penetrate deeper and are more durable than water-based ones. However, some people still choose water-based dyes for their easy cleaning properties. You can also opt for a hybrid stain that is both oil- and water-based. This type of dye will penetrate deeply, retain color longer, and only requires cleaning with water or soap.

Moreover, you can choose from staining with different shades, opacity, and finishes to suit your purpose. For instance:

– If you want to paint floors and stairs where many people pass by, it’s best to choose transparent and semi-transparent stains.

– If you want to cover wood defects or surface damage, use opaque or solid stains.

– For the highest UV protection, but without penetrating the wood, you can use solid color stains. However, this type of dye will likely leave a surface film that can peel off over time.

Step 2: Giving the Wood a Good Scrub

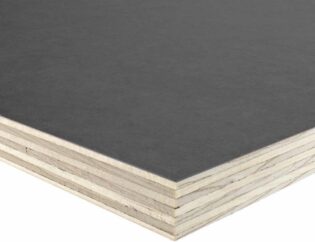

To stain pressure treated plywood, it’s important to prepare the wood surface first. Begin by ensuring that the wood is completely dry. Refer to the tips above on how to test for dryness. For new wood, you can simply sweep it or sweep away dirt and debris with a floor brush. However, if the wood is older and has stains or mold, it will need to be cleaned and dried before staining. Use detergent TSP (trisodium phosphate) and a scrub brush to scrub the wood surface if mold or stains are present. Follow these steps to clean the 4×8 pressure treated plywood surface:

- Use a stiff brush to remove all dirt and debris

- Then, scrub the wood with the following floor cleaning solution: 1 gallon of water, 1 quart of rubbing alcohol, and 1 quart of oxygen bleach (like OxyClean).

- For surfaces heavily soiled with mold, mildew, or other stains, use a cleaner and follow the manufacturer’s instructions.

- For painted or varnished wood, remove the paint with a wood stripper before staining.

- Finally, rinse the pressure treated plywood with clean water to remove any residue.

By following these steps, you’ll ensure that your pressure treated plywood is properly prepared for staining, resulting in a beautiful finished product.

Step 3: What You’ll Need – Tools & Stuff for Staining

The next important thing is to make sure you have enough tools & stuff to perform the job of staining pressure treated wood. Consider the scale of your project and make appropriate use of brushes, rollers, stain pads, or even sprayers to stain pressure-treated wood.

Each type of tool will have its function, for example:

- If you need to tackle tight spaces and stain areas with precision, use a brush. They are the ideal choice for jobs that require high detail and require a lot of time and effort

- The roller and dye pad provide a good balance of speed and high precision

- The spray bottle will help you handle the dyeing process quickly. However, a spray bottle will not work if you want to dye a very thick layer. To use the spray effectively, you need to be careful when spraying and avoid overspray

- The extension column makes rollers and pads easier to use.

In addition to the items mentioned above, you also need other items such as stirring sticks, cleaning cloths, cloth or plastic sheets to protect the surrounding area. Dyers also need to wear protective gear such as splash-proof glasses and gloves. Wear long pants, long-sleeved shirts, and boots or closed-toe shoes to keep yourself clean.

Step 4: Deciding on That Exterior Stain, Again

Choosing the right type of paint for pressure treated plywood can be a challenging task, especially when it comes to exterior projects such as decks, fences, or door closures. There are several factors to consider when selecting a paint that will both protect and enhance the surface.

Firstly, pressure laminate wood has undergone a chemical process to prevent termite and mold damage. As a result, it is essential to choose a paint that can withstand the chemicals used in the wood treatment and provide a protective coating against external elements.

Secondly, it’s crucial to consider the environment in which the wood panels will be used. If it will be exposed to direct sunlight or rainwater, you need to choose a UV-resistant and waterproof paint to protect the wood from fading and rotting.

Finally, it’s important to keep in mind the aesthetic aspects of the project. The color and pattern of the paint should match the style and design intent of the exterior project.

Step 5: Another Round of Cleaning

Regular cleaning is crucial to maintain and preserve pressure treated plywood used in exterior projects such as decks, fences, or garden areas. Dirt, grime, and mold can accumulate on the surface over time, making a follow-up round of pressure laminate cleaning an important task.

When cleaning pressure laminate, using the right method is essential. For light stains, you can use a soap and water solution or gentle wood cleaning products. However, for the heaviest stains or mold, you may need to use special cleaning agents or chlorine solutions.

In addition, high water pressure or a stiff brush may be necessary to remove stubborn stains and provide a deeper clean. However, care must be taken not to damage the surface of the wood or remove the protective coating.

It is also necessary to clean the tools used for staining to avoid dirt sticking to the paint layer and being unable to clean it once the stain layer has dried. Failure to do so can cause pressure-treated plywood to lose its aesthetics.

Step 6: Keeping Your Green Friends and Nearby Areas Safe

Before starting the process of painting pressure plywood panels, ensuring the safety of trees and surrounding areas is an important issue to consider. The use of chemicals in the cleaning and painting process can affect the health of plants and even harm the natural environment.

One way to protect trees and surrounding areas is to use protective measures such as shielding, tarpaulins or umbrellas to protect trees and lawns. This helps prevent chemicals in paint and cleaning solutions from coming into direct contact with plants and soil.

In addition, choosing paint products and wood cleaning solutions that do not contain toxic substances is also an important measure. Products that contain low VOCs (volatile organic compounds) and do not contain lead or heavy metals will minimize risks to human health and the environment.

When working near trees and surrounding areas, it is important to pay attention and be careful to ensure that no chemicals enter the soil or groundwater. If there is any waste generated during work, collect and dispose of it properly to avoid negative impacts on the environment.

Step 7: Getting Down to Staining

Once you’ve made sure that the pressure treated plywood is clean and dry, it’s time for the plywood to be ready for dyeing. Check the weather forecast, choose a nice day, cool weather, and especially no rain within the next 24 – 48 hours.

First, stir the stain thoroughly with a stir stick and pour a small amount into the paint tray. To avoid the color drying out, you need to stir continuously while working. Then, dab a little stain in the paint tray into a small corner or underside of the pressure treated plywood to make sure the dye color is exactly what you want. Use a paintbrush to paint gaps between boards and hard-to-reach places. For consistent results, avoid overlapping paint strokes. If you’re painting a fence, deck railing, or other vertical surface, start at the top and work your way down. Finally, let the stain dry for at least 24 hours.

Standard paint is dangerously slippery when wet and will wear off quickly when walked on. You may have to wait longer for the wood to dry to paint than to stain. If the wood is not completely dry, moisture can cause the paint to bubble and peel.

Before painting, you will need to apply a coat of exterior latex primer designed for pressure-treated wood. The primer will allow the paint to adhere to the wood properly.

Step 8: Time to Unveil Your Plants and Other Bits and Pieces

When painting pressure treated plywood, it’s crucial to remember to expose plants and other accessories to protect them from any harm and keep the surrounding space looking neat and harmonious. Before painting, use a tarp or drop cloth to cover or protect plants and other exterior items that you want to preserve. This step is even more important if you’re using harsh chemicals during the cleaning or painting process, which can be harmful to plants and unprotected items.

Additionally, if possible, move potted plants or other items out of the work area to avoid getting covered in dirt or paint. This helps protect them from any contamination and ensures they remain looking clean and beautiful even after the project is complete.

Step 9: The Cleanup Crew – Dealing with the Aftermath

After completing the process of painting pressure treated plywood panels, cleaning and handling the aftermath is an important part of ensuring a clean and safe working environment.

First, collect all painting tools and supplies and clean them carefully. Ensure that all chemicals and paint residues are collected and stored safely. If possible, recycle or dispose of them appropriately to minimize your impact on the environment.

Next, clean the work area to remove dirt and paint residue from the surface. Use a brush or stiff brush combined with a suitable cleaning solution to remove stubborn stains. Make sure the surrounding area is also cleaned to avoid leaks leading into the house or leading to environmental problems.

Finally, consider inspecting and maintaining the painted surface to ensure that it meets expectations and that no problems occur post-painting. If necessary, take steps to repair and refinish to ensure that the wood surface is preserved and looks good for a long time.

Step 10: Sealing the Deal on Your Stained Wood

If you want to preserve the natural look of the wood, apply a coat of clear or light-colored glue for added waterproofing and, depending on the type of glue, UV protection to help prevent fading.

H2: How Long Till You Can Stain Pressure-Treated Wood?

The length of time you should wait before painting pressure-treated wood typically depends on the moisture level of the wood and the weather. New wood often contains a large amount of water from the treatment process, and painting the wood while it is still damp can result in undesirable outcomes such as fading or uneven color.

As a general rule, it is recommended to wait at least 4-6 weeks after installing new wood before painting it. This period allows the wood to dry naturally and shed some of its excess water. However, the waiting time could be longer depending on the specific environment and weather conditions in your area.

H2: Is it better to paint or stain pressure-treated wood?

There are many questions about paint or stain pressure treated plywood. When painting pressure-treated wood, it will usually adhere better than paint. Because the preservatives in pressure-treated wood make it more difficult for the paint to adhere to the wood surface. But most of all, pressure-treated wood needs to be completely dry so it can absorb the paint or stain. For a beautiful, long-lasting finish, first assess the wood’s moisture content, then apply the correct stain or primer and paint.

4 Easy Tips for Nailing That Pressure-Treated Wood Staining

1. Scouting for the Top-Notch Stain

When you start the process of staining pressure treated plywood, it’s crucial to choose a high-quality dye. Ensure that you’re using a premium paint that sticks to the wood and safeguards it from environmental factors such as water, sunlight, and termites. Explore the available products on the market and consult with previous users to ensure that you’re selecting the right product that suits your requirements.

2. Getting Your Surface All Prepped and Ready

After choosing the right paint, you need to clean and smooth the pressure treated plywood surface. Remove dust and cracks, then make sure the surface is dry before dyeing. Careful preparation will help the paint adhere better and provide the best results

3. The Art of Stain Application

Stain pressure treated plywood requires precision and technique to achieve the desired surface finish. Start by applying the dye evenly across the wood surface with a brush, roll, or sprayer, following the wood fibers to get an even result. Take care to avoid creating runs and overlapping marks, maintaining an even coating over the entire surface. Wait for the dye to penetrate the wood for the recommended time before wiping off any excess with a clean towel.

4. Going for the Solid Color Look

Choosing a bold and consistent color is a popular choice when wanting to create a strong and impressive wood surface appearance. A solid coat of paint will hide the wood grain and create a uniform surface, highlighting the shape and structure of the material. When performing the painting process, be sure to apply an even layer of paint over the entire surface and control the thickness of the paint layer to avoid creating rough or uneven spots. A coat of bold color paint will make the wooden surface special and personalize the space uniquely.

At VINAWOOD blog, we answered the question: can you stain pressure treated wood? Hope this article will help you in the process of staining 4×8 pressure treated plywood. If you want more information about plywood types, please check out our website.