Finishes are elements fixed to the final structure of a modular furniture. They are the final surface of the material and are used to protect it from impact, water, frost, corrosion, abrasion, stains et al. Finishes are also used to offer style, texture, color and uniqueness to modular furniture design keeping with the overall interior design theme of the room. Laminates, acrylic, veneer, lacquered glass are some examples of finishes that are used on shutters, wardrobes, cabinets, entertainment units and other surfaces

Knowing the right type of finish will help prevent surface checking or cracking and will ensure long-term durability and performance. In this article, we will give you a guide to finish plywood with many professional tips and techniques. Moreover, we will together discover the best methods for sealing, staining, and protecting your plywood projects for a professional look and high quality.

How do you finish bare plywood?

A traditional and affordable option for bare plywood is paint. However, achieving a long lasting and attractive finishing requires a number of steps:

- Sanding:Sand the plywood with fine-grit sandpaper (150-220 grit) to smooth out the surface and the filled areas. Always sand in the direction of the wood grain.

- Applying Primer: Use a brush or roller to apply a thin, even coat of primer. Let it dry completely according to the manufacturer’s instructions.

- Painting with your desire color: Apply the first coat of paint with a brush or roller, ensuring even coverage

- Painting on a clear coating to finish: Let the first coat dry, then sand lightly with fine-grit sandpaper to remove any brush strokes or imperfections. Clean the surface thenapply a second coat of paint and let it dry thoroughly.

- Apply a protective finish

> Read more: plywood oriented strand board, roof plywood, plywood projects, pressure treated plywood, floor joist spacing

How do you finish raw plywood?

When it comes to raw plywood, there are occasional projects where we don’t want to see that iconic edge. At those times, i will give you three good ways to hide the stripes before painting, staining or clear finishing:

- Option 1: You can use a wood filler that can be sanded and painted to give your plywood project the appearance of solid wood. Similarly, spackle is designed to provide a smooth, finish-ready edge. Both wood filler and spackle can be applied quickly with a putty knife, though some find that spackle is easier to apply, dries faster, and sands more smoothly. Try both products to see which you prefer.

When using either product, start by identifying any areas that need filling, such as small gaps between plies (voids) or minor chips along the edges. Then, apply an even coat along the ply edge, ensuring it is fully covered. After this coat dries, use fine-grit sandpaper (#150-180) to create a smooth finish. If necessary, apply a second coat and sand it again to achieve a surface that is ready for painting.

- Option 2: Various types of trim molding, which are narrow strips of solid wood, can easily conceal plywood edges by covering them. Screen molding is ideal for 3/4″ plywood, while lattice strips, available in several standard widths, are suitable for other plywood thicknesses. Attach these trims along the edges using thin finishing nails. Then, fill the nail holes and seams with wood filler or spackle, sand them smooth, and prepare the surface for painting or staining.

- Option 3: The third and final concealment strategy, known as edge banding, covers plywood edges with thin strips of natural wood. Edge banding, which comes in a roll like tape, is available in various species and widths to match your plywood. It can be painted, stained, or coated with polycrylic, and it’s easy to apply using a household iron set on cotton (no steam).

- To apply edge banding, cut a strip an inch longer than your plywood edge and position it along the edge. Use the iron to melt the dried wood glue on the underside, bonding the strip to the plywood.

- While the strip is still hot, press a woodblock along its length to apply pressure and eliminate air bubbles, ensuring a tight seal. Trim any excess and check for a strong bond along all edges and ends. If there is any lifting, reapply heat with the iron.

- Smooth the ends and edges with 220-grit sandpaper until they blend seamlessly. If you find any spots where the glue didn’t bond, reapply the iron. Finish the edge banding as you would any natural wood surface, with paint, stain, or clear coat.

> Read more: laminate flooring, hardwood flooring, baltic birch plywood, maple plywood, ACX plywood, BBOES plywood

What surface finishes can you apply to plywood?

- Laminates: Laminates are a finish made from very thin sheets of wood or paper and plastic resins. These are pasted on the core material (such as commercial plywood) using glue and a machine press. The upper layer has a decorative design or a color. There are many types of laminate finishes such as textured, non-textured and high gloss.

- Lacquered Glass: Lacquered glass is commonly used for furniture, such as kitchen and bathroom cabinetry, as well as for decorative elements like walls and partitions. Its high-gloss finish can add a modern and sleek touch to a space, and the ability to customize the color and pattern allows for greater design flexibility.

- Veneer: Veneer finishes are popular for their ability to imitate the look and feel of solid wood at a fraction of the cost, and for their versatility in allowing designers and manufacturers to create unique and custom pieces. Veneer finishes are also more stable and resistant to warping and cracking than solid wood, as the thin layer of veneer is less affected by changes in humidity and temperature.

- Acrylics: Acrylic finishes are commonly used in high-traffic areas and for items that are frequently handled, such as kitchen cabinets, countertops, and bathroom vanities, as they are durable and easy to clean. The glossy finish of acrylic can also add a modern and sleek look to a space. The range of colours and transparency options allows for greater design flexibility.

- Duco: Duco finish is commonly used in furniture, cabinetry, and other decorative items to add a sleek and modern look. It is also popular for use in high-traffic areas, as the glossy surface is durable and resistant to wear and tear, fading, and staining.

What is the cheapest finishing material to plywood?

The cheapest finishing material for plywood is paint. It’s not only a cost effective solution but also offers a wide range of colors and finishes, allowing you to customize the appearance of your plywood project. Latex or acrylic is typically the cheapest option and can be applied easily with brushes or rollers. Additionally, paint provides a protective layer that can help extend the life cycle of the plywood by prevent it from moisture and wear.

> Explore further: MDF vs Plywood, Particle Board vs Plywood, OSB and Plywood, plywood ceiling

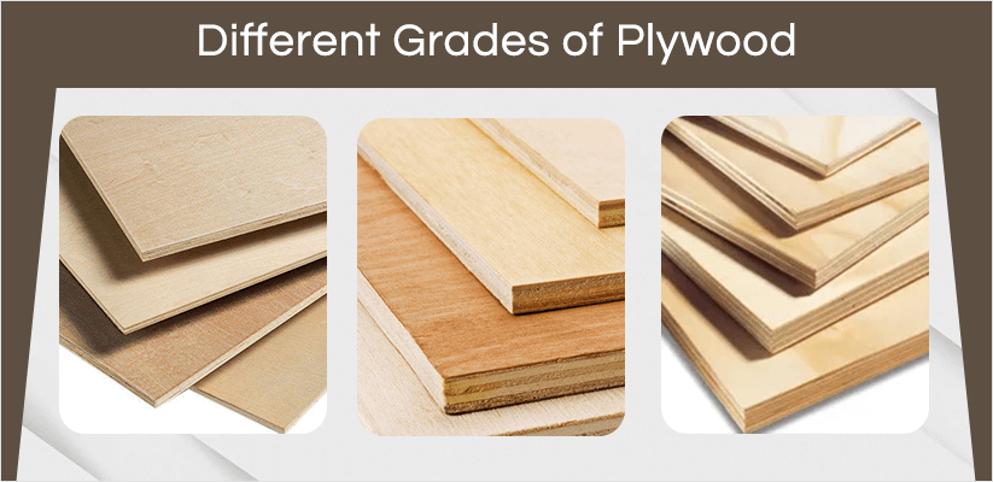

What is the best finish grade plywood?

The best finish plywood will be the A grade plywood, A-grade plywood features a smooth, sanded surface that is free from knots and other imperfections, making it ideal for projects where the appearance of the wood is important. This grade of plywood is often used for cabinetry, furniture and other visible applications because it provides a high quality finish that can be painted stained or left natural.

For even higher-quality finishes, you might consider AA-grade plywood, which is used for premium projects and offers an exceptionally smooth and defect-free surface. This grade is perfect for high-end furniture, detailed woodworking projects, and other applications where the finest finish is desired.

There are many types of plywood finishes that you must know before simply making a purchase. The key is to make sure that you get the right type for your needs. To avoid any mistakes with your decision on plywood finishes, seek the advice of an expert plywood sheet supplier.

If you need any help in determining which plywood finish will work with your project, why not contact us at Vinawood.com today? We’ll be happy to guide you

> Learn more: